Due to changing demographics in the family at the beginning of this century, one of the rooms became a guest room. In addition to the standard set of furniture, the room contained a single bed, occupying almost two square meters of the small area of the room. I decided to get rid of a bed that wasn't used often and install a stationary lift-up bed instead. I wanted to buy a folding bed at a brass store. The price of such a bed would not only surprise, but shock. If these were still high-quality products made from real materials, then the conversation about purchasing could still be had, but these were some clumsy and cumbersome options. Financial assessments have shown that it is very profitable not to buy a bed, but to make it yourself. A trip to the building materials store confirmed the implementation of the plan to build a homemade bed, but one snag arose: in 2006, I was unable to purchase any mechanisms for building a lift-up bed. Over the course of a month, I drew up various sketches of lifting beds, from simple ones to mechanized ones with electric drive. The requirements for the bed design were as follows. 1. Maximum compactness. 2. Parallel use of the bed for other purposes. 3. Easy to open and close. 4. Reliability of the mechanism for unfolding and fixing the bed in the raised state. 5. Use of environmentally friendly materials. 6. Easy to manufacture.

See the result of my work, drawing, instructions and manufacturing diagram with photos and videos are attached.

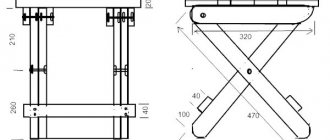

Bed sketch

DIY folding bed

Almost no one has a large and spacious apartment that would contain all the elements of furniture, including a spacious bed.

Often, it is the double bed that takes up most of the free space in the room, and therefore, placing anything else is extremely problematic. This option does not suit anyone, so now it has become a real trend to create your own furniture yourself, because due to this you can create a variation that is unique in terms of design and comfortable, made for yourself. In small studios, it is recommended to give preference to folding beds that can easily fit there; if necessary, they can be removed.

In this article you will learn how to make them yourself.

Advantages and disadvantages of lifting beds

The main advantages are:

The upholstery does not collect dust;

Doesn't take up enough space, you can save space in the room;

The furniture is completely inconspicuous when assembled; the frame is made in the form of a shelf, chest of drawers or cabinet.

Unfortunately, there are also shortcomings. It is impossible to move the bed to another place. This is because it is attached to a frame that is firmly attached to the wall and floor. If you want to make a bed without the help of others, then you will need a lot of physical effort, a lot of free time and at least a little experience in assembling furniture.

What you need to create a folding bed with your own hands: materials and tools

If the folding bed is made independently, and all operating rules are followed, then such options look much more beautiful than the options offered on the market for a similar price.

By following all the rules, you will be able to create a mini-bed for yourself for 10 years. In addition, you can always accommodate a guest for the night. The main thing is to strictly comply with all the requirements and nuances; by assembling the folding bed according to the instructions, you will have furniture that will serve you for a long time.

At the very beginning of creation, it is necessary to consider what materials will be used, as well as the approximate appearance of the product. The choice is quite large - metal, solid wood or MDF materials are suitable. If you have a very limited budget or just don't want to spend a lot of money, pay attention to the last point. Fiberboards are inexpensive, but they have excellent properties that can be realized in operation. Firstly, a structure made from this material does not lose its properties for a long time. Secondly, you are guaranteed an attractive visual component. Thirdly, due to the average density, operation under medium load conditions is allowed. Anyone can work with this product, even a beginner.

It is best to use materials made of wood, because it is many times more profitable compared to metal structures, because environmental friendliness and heat retention are many times higher. This article will look at creating a folding bed from MDF. You will need to stock up:

- measuring instruments;

- circular saw;

- pencil;

- grinding angle;

- drills;

- sandpaper;

- safety glasses.

Above, only the tools for making a clamshell with your own hands were indicated. It is worth noting that before assembling it yourself, you need to carefully study several articles, as well as videos, in order to better understand the topic, find out possible difficulties and features, otherwise you may not like the finished clamshell.

Features of the design of the mechanism for a folding bed using a practical example

To implement complex furniture projects, you always need to use certain technologies that will ultimately provide the desired quality result and long-term operation. The production of a horizontal folding bed requires a special approach and is carried out taking into account certain rules. The key points in this topic are considered to be “points of contact”, which provide the opportunity to transform from one furniture object to another.

Here are the design features using the example of combination with a cabinet:

- By using a jig, holes are made in the side panels of the closet and bed.

- This is done to connect the walls with special dowels.

- On the reverse side, metal plates are installed that connect the plate doors.

- For sliding facades, longitudinal grooves are used.

- Due to the side edges, the mattress will not move to the sides.

- The retractable leg is often attached using a tube passed through the frame of the structure.

- A cornice is used to disguise the fasteners.

- The last step is to screw the support legs to the side parts.

Compliance with these actions is the key to high-quality implementation of the mechanism for a folding bed in practice. In exceptional cases, separate technologies may be used when non-standard materials are used for production.

You can buy a bunch of different furniture that will fill most of your apartment, but from a design point of view it will not always look aesthetically pleasing. Therefore, new furniture with multifaceted functional solutions is constantly being developed. Based on the above information, you are already convinced that modern designs are surprisingly easy to use and also have a number of advantages, so making the right decision on furnishing your apartment will be much easier.

Technique for assembling a clamshell

How to make a folding camp bed with your own hands? You need to start the creation process by creating or searching for high-quality drawings, because an inept drawing made without rules can ruin all your endeavors. If you can't make them yourself, find them online or ask a professional to make them. Yes, it will cost a little more, but then the most important part will be completed. Sequencing:

- Depending on the materials used, you need to find two supporting boards, their length should be equal to the length of the mattress, which is purchased separately.

- We have selected an option, then, based on its dimensions, cut the boards to the required length. It will serve as “sides”. It is worth noting that the transverse elements should always be slightly larger relative to the width of the mattress in order to be able to connect them with the supporting elements.

- Connect the back wall.

- At the next stage, a shelf is made, onto which the base is subsequently attached. Using supports, secure it.

- Then you have to create your own box for the mattress. The structure should have the following dimensions (select depending on the mattress you choose) - 110 x 1460 x 2000 mm. Attach it to the middle of the bottom. After this, plywood is used to complete the structure.

- If desired, the use of any decorative products is allowed. It is worth remembering that the color should match the overall interior of the room.

The resulting folding bed needs to be decorated, because now it has far from the appearance that we would like to see. You can use paint, but you need to be careful.

Preparing for the assembly process

Let's look at several features of the implementation of this modern idea. First, choose what kind of bed you want to make - horizontal or vertical. Decide on the material later. Fortunately, the modern construction market offers a large selection of options. You can take natural wood, chipboard or MDF.

The main thing is to pay attention to the technical properties. The material must be environmentally friendly, reliable and durable. It’s also worth choosing the tools for the job. If you don’t have an electric drill, a screwdriver, a screwdriver, a hammer, a saw, various drills, self-tapping screws, and screws at home, then it’s worth purchasing all of this. You will need them during work.

DIY folding bed

Today, stores offer many furniture options. Despite this, some people find it difficult to choose the right piece of furniture that would perfectly suit their home. Folding structures have become popular today. A transformable sleeping place helps to easily solve the problem of a small room, and a do-it-yourself folding bed becomes the best option.

What types of folding beds are there?

Folding sleeping places, or, as they are also called, transformable beds, come in different types. They are selected based on the interior of the house and focusing on taste preferences.

A wall folding lift bed is secured to a concrete or brick surface. It is important that the wall can support a lot of weight, so plasterboard partitions are not suitable for installing the structure.

The body, which looks like a box, completely includes a bed with a mattress and even a bed, which simplifies getting ready for work in the morning. The entire structure is securely fastened with fasteners. If shock absorbers are used in the manufacture, the stock folds easily. Even a child can do this.

Folding furniture is an excellent choice for those who have little space in their apartment. Its mechanism and frame are easy to assemble. Even a novice craftsman can make a folding bed, but it will look presentable. The furniture will fit perfectly into almost any interior.

Types of fasteners

Fastening such structures does not require special skills, it is correctly described in the attached instructions, so the main work when installing a folding bed is binding to a specific layout, built-in furniture, compliance with design proportions and installation instructions. This kind of work can be done with your own hands, without the help of specialists, especially if you already have experience assembling furniture.

When installing structural elements, it is necessary to carefully mark the mounting holes for fasteners to ensure the stability of the bed and facilitate the installation process.

The kit for making a folding bed, along with fasteners and structural elements for mounting the bed frame, often includes gas shock absorbers or, as they are sometimes called, gas lifts.

They facilitate the transformation process so much that even a child can disassemble and assemble such beds. Sometimes, in order to reduce weight, a bed frame structure made of light non-ferrous metals and non-metallic linear springs is chosen.

How does a folding bed work?

The operating principle of a transforming piece of furniture is quite simple. There are 3 types of lifting mechanism.

Spring is a budget choice. Although springs can withstand a lot of weight and load, they quickly wear out and fail.

The gas mechanism operates on shock absorbers, which makes it more reliable and convenient to use.

In contrast, the stock is also equipped with manual lifting on hinges. Although this mechanism is much simpler to manufacture than the previous two, it is also much more difficult to use. To fold or unfold a sleeping place, you need to put in a lot of effort.

Horizontal bed

The design features of this model repeat the previous project. We have a bed, a box, a lifting mechanism. The dimensions of the frame for a sleeping place are slightly different, so the depth will be 41 cm, length – 200 cm, height – 112 cm. The given characteristics are conditional and for each individual project will depend on the size of the bed and mattress.

Materials and elements

For the headboard, chipboard about 2 meters wide is suitable. Prepare the preparations in advance. You will also need about 6 meters of timber to build the frame. The bed will also require the following components:

- four chipboard parts for side and internal elements, sizes 1080*394*19 mm and 1080*265*19 mm, respectively;

- two chipboard elements for the folding bed cover – 2020*400*19 mm, and also for the shelf – 972*390*19 mm;

- two small shelves for chest of drawers decoration – 980*310*19 mm;

- two guides – 2000 mm;

- cornice – 2020*992*19 mm.

Assembly

The bed is assembled using screws. The whole process repeats the assembly of a vertical folding bed model. To prevent the mattress from moving, you can attach a special edge about 1 cm long along the edge of the frame.

In furniture stores, the price of such furniture is often quite high, which makes it inaccessible to many consumers. Therefore, independent implementation of the folding bed project is a burning topic. It will cost much less, and the result can exceed even your wildest expectations.

Additionally, watch the video to understand everything in more detail:

How to make a folding bed with your own hands

Making a folding bed is not difficult at all and is even more reliable and practical than purchasing a ready-made piece of furniture.

What does it consist of - drawings

Before manufacturing the product and purchasing the necessary materials and tools, you should make the correct drawing of the lifting structure. The simplest and most presentable transforming bed consists of a lifting mechanism, a powerful magnetic clasp, a frame and a cabinet. The lifting mechanism is the most important component.

The manufacturing process begins with the creation of a frame diagram. It has the form of a frame and elements of a bed box, to which the legs (wooden or metal) are attached.

The correct design of a folding sleeping place can make the room more spacious. The bed can be either double or single.

Materials and tools

To make reliable furniture with your own hands, you will need high-quality materials and a suitable set of tools.

It is advisable to use chipboard. A folding mechanism, self-tapping screws, and furniture screws are required. You can’t do without a tape measure, an electric drill, a set of keys and screwdrivers, and a level.

Assembly of the structure

Frame assembly begins with the manufacture of the bed frame. It will require 4 boards of the same size. The structure is firmly held together using glue and wooden pins. After the glue has dried, to ensure the reliability of the box elements, they must be fastened using self-tapping screws and furniture corners. The base can be made either from a whole piece of plywood or from a large number of boards knocked together.

The cabinet frame also needs to be strengthened with self-tapping screws, then connected to the wall using corners. The product must be attached as high as possible.

It’s not difficult to make the legs for the base of the bed yourself, but if you don’t want to waste time, you can buy them at a building materials store. Attaching the folding bed lifting mechanism should be carried out according to the manufacturer's instructions, which are always included in the kit.

To prevent the structure from becoming loose, it is necessary to prepare the walls (it is better if it is a load-bearing floor) and the floor. They should be even.

Many people believe that it is good to use mirrors to decorate the front of the bed, but this should not be done under any circumstances. Firstly, the mirror will not withstand the loads when raising and lowering the structure and will subsequently crack. Secondly, the reflective fabric will add extra weight to the bed, which will complicate the operation of its mechanism

It is necessary to carefully approach the choice of materials. The use of low-quality or damaged ones is not allowed. To make your own bed reliable and neat, work can begin only after carefully studying the drawings.

All installation work must be carried out on a flat surface. It is important not to forget about precautions and safety. It is necessary to carry out the assembly carefully and constantly check that the angles are maintained at 90°.

It will take approximately 2 months to completely assemble the bed along with other daily tasks. If you try hard, you can cope in a month. When assembly and manufacturing is carried out in stages and the exact geometric proportions are observed, the bed will turn out beautiful and of high quality.

You can also buy furniture with a folding sleeping area in the store. But, if you follow all the instructions, assembling the bed will not seem difficult, and the result of the work will decorate the room and give you the opportunity to rest peacefully at the end of the working day in coziness and comfort.

Self-assembly of the structure

Having chosen the appropriate design kit for a folding bed, they begin to assemble the box, the place where the bed is removed. The box must be securely attached to the wall and floor, otherwise, when assembled, the bed may suddenly fall; when disassembled, the structure of the box may tear off the wall. If the wall in the room is plasterboard, then it is necessary to use long fasteners that will pass through the plasterboard, securing it to the concrete or brick wall.

After installing the box, a bed is made, having carefully studied the complete set of connecting elements and assembly instructions.

To make the bed of folding beds, solid wood or laminated chipboard is usually used. The first option is a more reliable, environmentally friendly and lightweight material for the bed. Its only drawback is its higher cost. The geometric dimensions of the bed are determined by the selected mattress. Having cut the material, sawed it, marked the fastening points, they proceed to assembly. During installation, you should carefully check the reliability of all connections and perform additional gluing of structures, because during operation the folding bed will be constantly subjected to mechanical stress.

The last stage of collection is the installation of gas elevators, blockers for spontaneous reclining of the bed, and securing the mattress using special belts. Upon completion of this work, you can begin testing the mechanism. First of all, check for the absence of distortions and jamming during the process of folding and unfolding the bed. If there is noticeable resistance to the transformation mechanism, adjustments and adjustments are made to the installation elements. There is no need to rely on the expression “it will develop”; most likely, the mechanism will “loose” and “break” over time, thereby complicating further adjustment work. You should also check that there are no gaps in the legs of the unfolded, unloaded bed relative to the floor, if any, and make additional spacers. Before starting operation and thereafter, it is periodically necessary to lubricate the moving joints with grease or other thick oils. To increase the service life of the folding bed, it is necessary to constantly check the condition of the fastening elements and, if necessary, replace them.

We recommend other articles on the topic

Do-it-yourself bed with a soft headboard - step-by-step instructions

Assembling and decorating a coffee table with your own hands, dimensions, photos, drawings

Standard sizes of kitchen cabinets

PVA glue - composition, technical characteristics, application

How to make a bed with your own hands

Despite the large selection of ready-made furniture, many people spend a lot of time and effort searching for a suitable wardrobe or bed. Various models are sifted through the “sieve of doubts”, differing from each other in design, color and size, but nothing fits. This is exactly the problem that a user of our site with the nickname avamonster encountered, and a homemade bed became an excellent way out of the “furniture dead end” for him. In this article we are making a bed together with our user!

– Review of lifting bed models. – What tools and materials are needed to make a bed. - Operating procedure.

DIY bed

I need a transformable bed for my house that can be quickly and easily stored in a closet against the wall. When folded, the front part of such a bed should be completely identical to the “facade” of a regular wardrobe. Therefore, there should be no protruding handles, protruding legs, etc. outside. Such a bed should not take up much space. When unfolded, the “transformer” should turn into a fully functional bed designed for comfortable sleep, and not a guest “crib”.

- You need a transformer for a standard mattress size of 1600x2000x150 mm, like a normal sofa; The height of the unfolded bed should not exceed 45-55 cm;

- The width of the transforming bed is equal to: the width of the mattress (1600 mm) plus the thickness of the side walls of the cabinet made of chipboard. That is, approximately 1632 mm. The depth of the bed is equal to the depth of the cabinet - 450 mm. When unfolded, the length of the bed should not exceed 2100-2200 mm;

- In the open position, the folding bed should fit well into the interior of the apartment, and not look like the simplest analogue of a “folding bed”. Should be easy and quick to clean;

- An unfolded bed should not take up much space in the house and interfere with free movement around the room, opening adjacent cabinets, cabinets, drawers, etc.;

- Safety: the bed should not have sharp corners that you can hit with your foot, hidden cavities and crevices where pets or small children can crawl into. The gas lift or opening mechanism springs should not be located near the sleeper's head;

- “Humane” price tag.

Design principle and design options

A wardrobe bed is a transformer consisting of a fixed wall box and a berth (bed) that can be raised and lowered.

More popular are transformers of a vertical design (longitudinal-folding), in which the head of the bed is attached to the walls of the box. They can be one-and-a-half, double, or less often single, and when folded they imitate a closet.

Cross-folding or horizontal transforming beds are mainly installed in children's rooms; they are also suitable for teenagers and short people. These are mainly single beds that recline sideways, and when folded they imitate a chest of drawers or a shelf. Sometimes horizontal beds are made into bunk beds, similar to shelves in a reserved seat carriage.

The bed of a vertical bed is usually made solid, but sometimes it is equipped not only with head hinges, but also with side hinges, and folds in half when put away in a box. The closet for such a transforming bed needs a deeper one, but its upper part can be used as a mezzanine for bedding.

On the sides of the box you can mount shelving in the same style, or make a folding bed part of a furniture set. Sometimes the bed is raised relative to the floor, and in the lower part of the closet there are small compartments for shoes, a bed with hinged doors or drawers.

DIY folding bed: product design

- Where exactly is the bed?

- Main components of the bed design

- Where to start the process

- Some recommendations

The main problem of apartments is their small size. You have to save every inch of space, arranging furniture in order to be able to move freely around the room. And if you decide to purchase a double bed, then placing the rest of the furniture in the bedroom will be problematic. Owners of one-room apartments can only afford a folding sofa, which even when folded takes up a lot of space.

Where exactly is the bed?

Bed frame assembly diagram.

This is exactly the question asked by friends who come to visit you for the first time. And all because during the daytime the bed hides in a niche as unnecessary, freeing up a large area for movement. Instead of a niche, you can use a frame in the form of a wooden cabinet, the width of which is several times smaller than that of a wardrobe. This type of folding bed is called a vertical one, since its folding mechanism is provided in a vertical position.

For a single folding bed, which can be placed in a nursery or as an extra bed on the balcony, you can use a horizontal lifting mechanism. This folding bed is located along the wall and can be disguised as a long narrow cabinet.

Return to contents

Which bed to choose

The first step in making a folding bed yourself is to determine its functional purpose. This can be a single or double bed for guests.

And also a transformable bed-sofa in a country house.

This could be a bed built into a wardrobe in a bedroom or children's room.

Then a suitable design is selected. The main elements of a folding bed are a box, a rotating device and a bed. Folding beds can be manufactured in vertical (the bed is folded across the length) and horizontal (along the length of the bed). The second option should be used when making a children's bed, as it requires less effort when tilting.

Main components of the bed design

Tools needed for work: circular saw, tape measure, pencil, corner, drills, Phillips screwdrivers.

There are four main elements that will make up a folding sofa bed:

- Mattress. Depending on needs, it can be single or double. The dimensions of the box-cabinet will depend on its size.

- Mechanisms for raising and lowering the bed. For these purposes, you can use the mechanical method and springs.

- The frame is the place where the sleeping place will be folded during the day.

- The bed on which the mattress will be placed.

Prepare the tools that will be needed during the manufacture and assembly of the bed:

- Roulette.

- Marking pencil.

- Sandpaper.

- Protective glasses.

- Drill.

- Phillips screwdrivers.

- Corner.

- Circular saw.

- Grinding corner.

Return to contents

Where to start the process

You should start with the manufacture of a general structure, which consists of a supporting box and the base of the bed attached to it by a lifting mechanism. To assemble the structure, you need MDF boards 2 cm thick, plywood 1 cm thick, nails, hinges, screws, magnetic fastener, wood glue.

You start by assembling the main structure.

Diagram of the transformation mechanism and dimensions.

To do this, you will need two supporting boards along the length of the mattress, to the dimensions which must be added to the desired height from the floor of the bed when unfolded.

- Let’s say the mattress measures 200 cm by 170 cm, then cut out 2 load-bearing boards 230 cm long and 40 cm wide, these will be the sides of the box. The cross bars should be longer than the width of the mattress, taking into account the thickness of the side walls (plus the gaps required for the side walls of the bed to overlap). Connect the crossbars to the supporting boards using self-tapping screws and wood glue.

Stage 2. After assembling the main frame, attach the back wall made of plywood using self-tapping screws.

Stage 3. Make a shelf on which the bed will be fixed on the headboard side, which supports the bed when assembled. Then secure the shelf inside the box with three supports 35 mm thick, and its upper part should be 20 cm above the floor.

Stage 4. Make a box for the mattress - the basis for the bed, which consists of a frame measuring 100x1450x1980 mm and a plywood bottom fixed in the middle, the size of which is 20x1410x1940 mm, it consists of two parts.

For manufacturing, take two side and two end boards with dimensions of 1980 and 1410 mm. Having previously made folds using wood glue and self-tapping screws, assemble the frame, then nailing the plywood bottom.

Stage 6. Making bed supports. When extending the bed, it must be placed on supports, peculiar legs, which are made of timber with a cross-section of 40x100 mm in the amount of 2 pieces. Attach the supports to the bottom of the bed using loops.

Stage 7. After the entire structure of the bed has dried well, attach it to the box body with wide hinges.

Stage 8. The mechanism for lowering and folding this bed can be chosen at your discretion. You can buy it at a hardware store.

Stage 9. In order to decorate the folded bed, you can use furniture shutters that will cover the timber supports. In another case, the supports can be made only in one place and are retractable. It is necessary to increase the height of the structure by the thickness of the legs.

Return to contents

Necessary materials, tools, cutting and bed design

Materials:

- sheet of plywood or MDF 12 mm thick (1 pc.);

- boards 2.5×30×240 cm (3 pcs.);

- board 2.5×20×240 cm (1 pc.);

- board 2.5×10×240 cm (1 pc.);

- board 2.5×7.5×240 cm (1 pc.);

- boards 2.5×5×240 cm (3 pcs.);

- decorative strips 6 mm thick;

- 50 mm self-tapping screws;

- 50 mm nails;

- 30 mm nails;

- 15 mm parquet nails;

- glue;

- wood putty;

- sandpaper;

- hinges (strong door hinges or special hinges for folding beds);

- heavy-duty magnetic latch that can hold the bed in the raised position and prevent it from tipping over;

- hinges with a closer for slowly lowering the bed to a horizontal position.

Tools:

- roulette;

- square;

- pencil;

- hammer (can be replaced with a gun for hammering parquet nails with a hammer);

- protective glasses;

- Kreg Jig – a device for drilling holes for flush-mounted miter joints;

- drill;

- a circular saw;

- gun for hammering parquet nails;

- eccentric sander.

A few general notes:

- Work on a clean, level surface.

- Take proper precautions and use personal protective equipment.

- Using a square, check after each step that the corners of the structure do not deviate from 90 degrees.

- Use quality, non-warped lumber.

- Before screwing in the screws, drill pilot holes and countersink them.

- When starting to make your own folding bed, study the drawings presented here.

Cutting list

For "Box"

- 2.5×30×199.4 cm (2 pcs.) – side walls

- 2.5×30×107.3 cm (1 pc.) – bottom

- 2.5×10×107.3 cm (2 pcs.) – rear cross members

- 2.5×5×111.1 cm (1 pc.) – front cross member

- 2.5×5×195.6 cm (2 pcs.) – finishing of the front side of the drawer, vertical sides

- 2.5×5×31.1 cm (2 pcs.) – finishing of the side walls of the drawer, top part

- 2.5×5×114.9 (1 pc.) – finishing of the front side of the drawer, top part

- 2.5×7.5×120.0 cm (1 pc.) – back part of the “ceiling”

- 2.5×30×120.0 cm (1 pc.) – front part of the “ceiling”

For "Bed"

- plywood 6 mm thick ×102.9×191.1 cm (1 pc.) – bottom

- 2.5×20×102.9 cm (1 pc.) – back wall

- 2.5×20×139.7 cm (1 pc.) – side walls (cut the board diagonally, as shown in the plan, to get two parts)

- Finishing the front side using 6 mm thick slats according to your wishes

Some recommendations

For better and reliable fixation of the bed when folded, you can use a decorative latch attached to the top of the bottom. Then you will definitely protect yourself from spontaneous unfolding of the bed.

When folded, linen and mattress can slide off the bed; to secure them, use 30 mm wide straps on both sides of the bed and fasten them with Velcro before lifting the bed.

Making a bed with your own hands is not difficult, if you have all the necessary materials and accurate drawings of the future product. Since everyone makes a bed to suit the size of their mattress, the final calculations may differ slightly from these figures.

Having learned how to make a folding bed (sofa), you can make a similar product for the dacha, replacing an old folding sofa or sofa with it, or preparing an additional sleeping place for guests.