Parquet or solid board

Those who have chosen wood as a material for their future floor will be faced with a choice between block parquet or solid boards. The choice is made by comparing these options:

- Various designs. Piece parquet is formed from many small elements (500x70 mm), allowing you to achieve various design executions. A solid board is a large layer of wood that is less susceptible to design processing.

- Laying technology. Installing parquet requires more time and effort than solid wood.

- Practicality of the coating. The parquet is subjected to scraping, which returns the original appearance to the coating every time. Repairing solid wood is a more troublesome process. The service life of parquet is longer than that of boards.

- Price. Piece parquet is more expensive than planks.

Advantages of piece parquet

Wood is a natural building material with the following advantages:

- environmentally friendly material, without harmful substances;

- durability;

- possibility of scraping (removing the top layer) up to 10 times;

- aesthetic appearance;

- additional thermal insulation;

- variety of choice;

- easy to repair and unpretentious to use.

Disadvantages of piece parquet:

- flammable material;

- not resistant to moisture;

- The material is demanding in terms of installation technology.

Disadvantages of piece parquet

Piece parquet has a lot of positive qualities, but it is not without significant disadvantages, which it is advisable to know about in advance:

- The high cost of dies, for the manufacture of which valuable or exotic wood is used. Repeatedly during operation, the floor covering is subjected to scraping, as a result of which there is a possibility that some fragments may become unusable, but it will be impossible to find an identical element for replacement.

- Floor coverings treated with varnish must be especially protected from mechanical damage, since when replacing damaged tiles, the difference in shades will be obvious.

- The varnished surface of the floor can be damaged by abrasive particles - sand, earth, dirt, so any contamination must be removed as quickly as possible.

- To prevent parquet blocks from deforming, there should be no sudden temperature changes or changes in humidity in the room.

- Damage to the integrity of the varnish coating can lead to moisture penetration into the wood with its subsequent destruction, so it is necessary to immediately repair the damage.

- Parquet flooring is very demanding regarding the preparation of the base and the microclimatic parameters in the room during installation: the air temperature should be 18-25°C, and the humidity should not exceed 65%. If these conditions are neglected, the dies will soon become deformed and gaps will form between them, and the floor structure will become vulnerable to moisture.

If we compare the pros and cons of parquet flooring, there are many more advantages and this is obvious. Negative consequences can be avoided by following the rules of operation of the coating, and its high cost is compensated by the unsurpassed decorative effect and long service life of the material.

Modular parquet

Parquet board and its installation

Today, parquet is presented in a wide variety of modifications: piece, solid, modular, panel or laminated. The material is environmentally friendly and is made from natural wood of the following species: birch, maple, oak, beech, ash, etc. There are also exotic varieties of materials for the production of this coating: merbau, wenge, mahogany, etc.

Many newcomers to construction work naturally have questions about installing parquet boards. It is important not to abandon this procedure if it seems complicated, since the result of the work will be a beautiful floor that fits into any interior. The high quality and originality of the coating will be noticeable even in the photo, not to mention a personal inspection. The service life of properly laid parquet is about 100 years, given its initially high quality.

Design

Block parquet is interlocking rectangular planks made of solid wood. The thickness of the boards is 14 - 22 mm, width 40 - 75 mm, length up to 500 mm. The planks have special locks in the form of a groove (niche) and a protruding part (ridge). Due to this design, the elements are connected quickly and reliably. Therefore, on laid parquet, the gaps between the elements are not noticeable.

The durability of parquet depends on the thickness of the wear layer (not to be confused with the thickness of the parquet), this is the layer of wood from the face to the crest of the plank. It is 7-10 mm.

Parquet boards - installation and dismantling

Another advantage noted by the manufacturers of these products is the ability to disassemble the floor, transport the boards to another place and reassemble it. Although in practice such a need arises extremely rarely, usually the covering is dismantled only to replace damaged boards.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

However, dismantling is a rather complicated procedure. Wooden floors react to fluctuations in temperature and humidity. Therefore, when dismantling the coating, the environmental parameters must be the same as during installation (which is necessary to relieve the load on the locks). In addition, when dismantling a three-strip board, the edge is often damaged, and after re-flooring, the coating no longer looks new.

Link on topic: Laying parquet boards with your own hands - master class for women

When floating installation, expansion (compensation) gaps must be provided between each room of the apartment at the rate of 1 mm per 1 linear line. m of room (measured perpendicular to the expansion joint). It is necessary to leave small (10-15 mm) gaps around the perimeter of the room, as well as in places adjacent to fixed structures (columns, stairs). On a properly laid floating floor, noticeable cracks appear much less often when the seasons change than on a floor glued to the base.

After all, the boards are softly fastened together and are able to move a little.

The floor expands and contracts evenly over the entire area, with its main “movement” occurring under the baseboards. However, when placing heavy furniture, the ability of the coating to respond to changes in humidity and temperature, as well as to slightly change its size, is reduced. In this case, you should prefer the method of gluing parquet boards to the base.

Criteria for choosing block parquet

There are no clear parameters for selecting the “best” parquet. It all depends on the operating conditions, but there are still some general signs of quality material:

- Parquet packaging must be sealed and free from defects, otherwise the material may lose its properties during storage or transportation.

- Wood should be dried using a special technology without exposure to high temperatures. The packaging indicates the drying method and residual moisture, the norm is 3-9%.

- Visual inspection is carried out by randomly selecting a pair of strips from different packs. When inspecting, pay attention to the evenness of the surface and the presence of visible defects (chips, cracks, etc.). There should be relief grooves on the back side of the plank - they relieve internal stress from the material and increase adhesion to the floor.

- The durability of parquet depends on the working layer. Therefore, it is better to choose a material with a wear thickness of 10 mm (not to be confused with the overall thickness of the strip).

- The type of wood is selected in accordance with operating conditions. If the room has high humidity, then moisture-resistant species are selected (teak, merabou, oak, etc.).

Now you know how to choose piece parquet, taking into account the characteristics of the operation of your home or other premises. Piece parquet will demonstrate its beauty and highlight the overall interior of the room. During operation, its surface is renewed by scraping and the coating takes on its original appearance.

Video - features of block parquet:

Do-it-yourself installation of parquet boards: photo

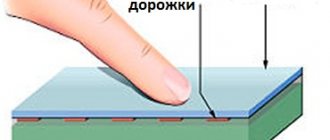

The boards are laid on a concrete base covered with polyethylene film and a sound-insulating substrate, or on a hydro- and sound-insulating substrate. The distance between the boards and the wall is adjusted using wedges (a). The elements are connected by aligning the grooves and tenons of the longitudinal and end sides (6, c). To remove gaps between the elements, use a striker (d)

© Author Ekaterina Ovchinnikova

TOOLS FOR CRAFTSMAN AND CRAFTSMAN, AND HOUSEHOLD GOODS VERY CHEAP. FREE SHIPPING. THERE ARE REVIEWS.

Below are other entries on the topic “How to do it yourself - for a homeowner!”

- How to lay parquet on a warm floor (underfloor heating) How to properly lay parquet on…

- Laying floor joists - calculation table How to calculate the thickness of the boards and...

- Do-it-yourself table made of laminated wood - photo and drawing How to make a desktop from...

- DIY flower container made of wood - drawing How to make a wooden container for...

- Canopy for a bathhouse made of cellular polycarbonate with your own hands How to make a canopy from…

- How you can measure the required amount of fertilizer using improvised means. Memo for the gardener - mass...

- Do-it-yourself telephone table with seat - how to make it, photos and drawings How to make it yourself, your own table...

Subscribe to updates in our groups and share.

Let's be friends!

With your own hands > Repair and design > Interior decoration > Floors > Methods of laying parquet boards

Methods of laying parquet and common patterns

Parquet can be different, but we are talking about laying piece parquet. This is the one that is assembled from numerous planks. They are sized so that the length is a multiple of the width - this allows you to assemble different designs. The simplest installation methods are flooring, which is called a “deck”. These are dies that are laid one after another, and the joints of the next row are offset by some distance. Most often the offset is 1/2 the length of the board or 1/3, and the third row is 2/3. The choice depends on the length of the slats. If they are short, then 1/3 will not be enough.

This is the simplest parquet laying scheme - offset decking

The second common installation method is herringbone, but it is too difficult to start learning how to lay parquet. There are also squares and all sorts of different braids, but mastering them is also a difficult thing. Obviously not the first time, when you have no idea what or why you need to do, and in modern interiors, parquet decking is more in tune. This is in classic interiors, and complex schemes are appropriate in large areas, but not in small rooms.

Yes, it’s beautiful, but it requires a specially created interior

There are two ways to install parquet: with glue and with glue + nails. Laying parquet with your own hands for the first time is easier and faster using glue. And then it will take you two weeks or more to build a small room. And if you nail each board with nails, it will take even longer. You need 2-3 of them per riveting (along the long part) and one at the end. And also tamp each plank so that there is no gap, drown the caps - in general, this is a task for the patient. And the glue holds the parquet no worse than nails. Nails are only needed at the initial stage to achieve good contact with the base and until the glue dries. Then they do not have any functional role. If you press each board well and do not walk on the parquet until the glue has completely dried, then laying the parquet without nails for the first time is the best choice.

Laying options

Today, there are two traditional options for laying parquet on a prepared base. This:

- Option for laying block parquet using special glue.

- Floating installation option.

Important! There is also a technology for fixing parquet boards using screws and nails, but this is used quite rarely, since fasteners spoil the appearance of this floor covering. Using the two methods outlined above, you can securely and efficiently fasten the floor covering without going into the details of the third.

Preparing the base for laying parquet

The base for laying parquet can be any: cement screed, concrete slab, wooden floor, dry screed. It is important that the floor is dry, without changes. That is, it must first be leveled. Plywood is laid on a dry, level base. Its thickness must be at least 2/3 of the thickness of the parquet boards. This means that if the parquet is 15 mm thick, the plywood should not be thinner than 10 mm; if the parquet blocks are 22 mm thick, the plywood needs to be 14.5 mm or more.

It is sold in large sheets, but it is cut into small fragments for parquet. If they are attached to a rigid base with small differences, it is enough to cut the sheet into 4 parts. When laying on a wooden floor or dry screed, the number of parts is greater. The sheet is divided into 6 or 8 parts, sometimes even into small fragments with a side of 40*40 cm or so. With this format, there is a greater chance that the parquet will not come off and will not creak.

Plywood is sometimes cut into very small pieces. Please note the seams are misaligned

When laying sheets of plywood, the rows are offset so that the seams of the previous row fall into the middle of the sheets of the next one. A gap of 3-5 mm is left between the sheets. They are also not placed close to the walls - the minimum distance from the plywood sheet to the wall is 10 mm. This gap is then closed with a plinth, but it can be filled with sealant.

To reduce the likelihood that the parquet will “rise” when laying straight along the wall, plywood is laid diagonally. And vice versa. This prevents the seams of plywood and parquet from matching.

Here's what we're talking about: the direction of laying the parquet blocks does not coincide with the seams on the plywood base.

The plywood sheets are attached to the base with self-tapping screws. The heads of the screws should not stick out. Holes are drilled for them, choosing a slightly larger drill diameter. If the base does not hold fasteners well (GVL, for example), it is better to additionally use glue, which is applied with a notched trowel. If the base is highly absorbent, it is better to coat it with a primer before applying glue. The primer is chosen for the glue, taking into account the type of base.

Sanding the plywood base for parquet is a mandatory step

After laying the plywood, wait 2-3 days. The glue will dry and the plywood will take on “working dimensions.” Now it is polished, ensuring that there are no differences in height that are formed due to the fact that the sheets are slightly different in thickness. Glue installation can also make a difference.

Tools and materials

For parquet laying work, certain tools may be required, as well as a number of materials. The list is approximate, since the need to use some of them will depend on the method by which the parquet is laid. May be useful:

- jigsaw or saw;

- grinding machines;

- drill, dowels and screws;

- hammer;

- measuring instruments and pencil;

- notched spatula;

- brushes and primer;

- moisture-proofing material;

- adhesive composition;

- nails, parquet staples;

- varnish

Notched trowel

It is necessary to pay special attention to the purchase of the parquet itself - its service life will directly depend on its quality. You should not buy low quality, cheap or damaged material. Also, the parquet must be chosen in a color that matches the overall style of the room where the renovation is being carried out.

Installation on concrete floor

On a note! Oak parquet is the most durable and reliable, as well as durable, but is quite expensive. Maple and beech materials are cheaper, but not much inferior in quality to oak.

PREPARATION OF THE SURFACE FOR LAYING PARQUET

Surface humidity should not be higher than 2%. Humidity is measured with a special carbide device (CM). Often, parquet installers will use an electronic instrument to measure moisture. However, this device has a fairly high degree of error. In order to obtain good adhesion of the glue that glues the plywood to the screed, it is necessary to prime the surface. The type of primer must match the type of adhesive, if rubber adhesive is used to glue plywood, then a solvent based rubber primer (eg ARTELIT SB-212) should be used. The primer is applied with a special roller.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

Step-by-step instruction

It is not necessary to call professionals to install parquet. All work can be done with your own hands. To do this, you must correctly follow the step-by-step instructions. The most important phase of installation is the preparation of a rough base for the coating . It is necessary to check the basis for the existence of flaws. The floor must be perfectly clean and level, without cracks or depressions.

There are several options for laying parquet boards with your own hands on different bases.

If the floor is concrete , it needs to be waterproofed, that is, covered with a special diffusion membrane or film. The membrane is joined with an overlap of 20 cm and secured with construction tape. The membrane is inserted onto the walls by 15 cm and secured with tape. Next, the floor is filled with a self-leveling mixture no more than 5 cm thick. This is the base for moisture-resistant plywood.

Plywood has its advantages:

- protects parquet planks from distortion;

- levels the floor;

- provides good heat and sound insulation.

After the screed has dried, it is coated with a primer and covered with plywood, the thickness of which is at least 12 mm. Sheets of plywood are cut into squares of 75x75 cm. This will protect the parquet from shrinkage distortions and will serve as a foundation for connecting the boards.

After all the manipulations, the screed is covered with glue and plywood is laid on it , which is pressed firmly and secured with self-tapping screws.

It is necessary to make gaps between the wall and plywood up to 2 cm. Between sheets of plywood it is necessary to make gaps up to 4 mm. This is required so that after expansion the parts of the plywood do not interfere with each other.

The next type of foundation is a floor on joists . A waterproofing film is spread over the concrete, then logs (beams 50x50 or 50x80 cm) are laid in increments of 35-40 cm and connected with corners and dowels. Next you need to lay the plywood flooring. Self-tapping screws are used for connection. You can also lay parquet on a wooden floor. To do this, it is necessary to inspect the coating for creaks, dips and other defects, only after that the floor is sanded.

If the base is a concrete screed, all work is performed as follows:

- the floor is sanded until completely smooth;

- dust and other debris are removed, paying special attention to corners and places near walls;

- apply the primer with a roller and coat all areas;

- sheets of insulating substrate are glued joint to joint and smoothed by hand. Next, you need to walk across the floor with a heavy roller for a tighter fixation.

The article mentioned lining material (underlay) several times, which is an important component for working with parquet.

There are several types of substrate:

- cork material compensates and levels the base if there are small unevennesses;

- cardboard is impregnated with water-repellent compounds and is ideal for heated floors;

- coniferous pressed roll material has good heat and sound insulation, but does not last long;

- material made from cork chips and bitumen has a high level of thermal and waterproofing, but it is prohibited from being used on heated floors;

- three-layer Tuplex consists of two layers of polyethylene film, between which polystyrene foam balls are located. This backing is designed to smooth out small imperfections in the base. Its main purpose is to create a ventilated gap under the finishing, remove moisture and level out minor defects in the base;

- Foamed and extruded polypropylenes have good heat and sound insulation. But such a substrate has a short service life, so experts do not recommend using it under parquet.

Once the base is ready, you can begin laying the parquet. There is a certain technology for working with parquet floors.

For herringbone installation, you need to use rectangular parquet flooring, which is laid at an angle of 90 degrees to each other, and to the wall - 45°C. The pattern of the entire floor depends on the first two rows. They set the direction of the entire floor covering. It is necessary to stretch strings from them for an accurate reference. To lay parquet in this way, you should use a special glue.

If you use the “floating” method for laying piece parquet flooring, then work starts from the corner of the longest wall from left to right. It is necessary to leave a distance of 6-7 mm between the wall and the first line of the parquet board, using mounting wedges . The second row is inserted into the grooves of the already placed row at an angle of 20°C and snaps into place. For good fixation, use a rubber hammer.

The adhesive method uses glue and small nails to fix the parquet flooring. The first line of planks is glued to the floor with a distance between the walls of 10 mm. Glue must be applied to the base and ends of the parquet, fastening it together. The boards are pressed firmly to the floor, excess glue is removed with a dry cloth. It is necessary to let the glue dry, only then continue work.

After the parquet is laid, the excess underlay and sound insulation that is visible are removed. The wooden plinth is installed using clamps. The baseboard is selected to match the color of the floor or wall, and you also need to pay attention to the size and texture.

On the market you can see wooden skirting boards with hidden connections to brackets and channels for cables. Skirting boards must be made from the same type of wood and purchased from the same batch.

When all the work on the parquet and skirting boards has been completed, the floor is sanded. This is necessary to remove defects and glue.

In the first and second stages, grinding is done with large grains, in the third - with fine grains . All manipulations are carried out with a grinding machine. Afterwards the floor is cleaned of dust and debris.

If necessary, fill the cracks. After it dries, excess putty is removed. The parquet is then varnished to protect it from moisture. It is advisable to apply varnish in 3 to 9 layers.

Block parquet laying technology

When laying parquet in straight squares, the planks are placed parallel to the walls of the room; there is almost no need to cut them. When laying parquet in an unfolded square, the planks are positioned to the walls of the room at an angle of 45°. The unfolded square can be made in a waste-free way. But for this you have to cut a lot of strips that serve as fillings for the triangles.

When drawing up a plan for laying block parquet in the form of squares, lay out a strip of planks along the width of the room. The length of the planks should be selected so that there is the least amount of waste. With the correct laying plan, the ends of the planks have to be sawed off only on one of the short sides of the room (at the end of the flooring).

Laying parquet with a straight pattern is quite simple, so an installation plan is not required. In order not to mow the first row of parquet, the cord must be pulled along the long axis of the room. Parquet planks can be used in any length, but the width must be the same.

The advantage of the slanting herringbone laying method is the ability to use parquet of different sizes for additions to the walls; parquet strips are cut only at right angles. The only drawback of this method is the complexity of mechanical scraping of the finished floor: passing through the parquet strip across the direction of the fibers can ruin the parquet. Before laying piece parquet in a herringbone pattern with or without friezes, it is necessary to lay out the rows of covering so that when laying the parquet there is as little waste as possible.

Is it possible to lay parquet on concrete?

It is possible to lay parquet not on plywood, but on concrete or cement screed, but only if the surface is flat. The method of installation is exclusively with glue, without additional fixation with nails. You need a special glue that, after drying, has a high degree of elasticity. Despite the fact that when laying parquet on concrete, fewer “auxiliary” materials are used, and there is less work, this is rarely done. The reason is that there is a high chance of getting a squeaky coating.

You can glue parquet directly onto concrete

The fact is that the temperature and humidity expansion of concrete and wood is very different. As a result, the parquet comes off the concrete. Even super-elastic glue does not always help. Torn planks rub against each other under load. We get creaky parquet. That’s why they lay plywood on top of smooth concrete or screed. It has intermediate thermal expansion - between concrete and wood and serves as a compensator, which ensures that the parquet adheres to the glue and does not creak.

The process of laying parquet with your own hands

Anyone can handle parquet installation.

Flooring methods:

- floating installation;

- installation using special parquet adhesive.

Stages of laying parquet.

There is another installation option when the planks are additionally secured with nails. This method is rarely used and is not practical. Floating installation means that the planks are joined together with a tongue-and-groove connection. This is the easiest way, anyone can do it.

The floating method is called because the parquet is not connected to the base, a single covering is located above it. This allows temperature and humidity changes to be properly controlled. The floor does not warp, cracks and crevices do not appear on the surface, and there is no squeaking. During installation, it is necessary to retreat approximately 1 cm from the walls - this will be a temperature gap.

Installation should begin on a layer of vapor barrier membrane, which is laid on a leveled base. Then you should lay a layer of sound insulation, which is perfect for cork. Its porous structure and unique properties make it possible to give the flooring the necessary characteristics. The floating coating is of high quality; if necessary, it can be easily repaired, i.e. replace damaged strips.

Adhesive installation of parquet is quite complex and requires attention and labor. To complete the work you will need:

- parquet planks of the selected type;

- special parquet glue;

- notched metal spatula;

- electric drill with a construction mixer attachment for mixing mixtures.

Scheme for laying parquet boards.

Before starting work, the base must be leveled, then covered with a layer of soil to ensure excellent adhesion of the glue and the base. The primer is selected depending on whether the floor is concrete or wood. Work should only begin at room temperature, the humidity level should be normal. After the primer has dried, glue is applied to the base in small sections, since the mixture will become unusable after 20 minutes.

The planks are attached not only with glue, but also with a locking connection . This installation method is the most durable. You should move from the far corner to the front door. After the parquet has been laid, it is necessary to sand the floor surface, for which special sanding machines with various attachments are used.

The first scraping is done using coarse sandpaper, then it is necessary to process hard-to-reach places and corners with an angle machine. The final sanding is done using fine sandpaper. It allows you to give the floor a smooth finish.

Varnishing parquet

Everyone chooses the type of varnish “for themselves.” Some people want a smooth, shiny surface, while others don’t want any shine at all. But these are only the external characteristics of the varnish. You need to choose it based on its basis. They are solvent-based, water-based and two-component (based on polymer resins).

If you like gloss, you need 5-6 layers

Those with solvents smell very strongly. They can give a high degree of gloss, but when objects are dropped they often chip. After some time, the mirror surface becomes covered with scratches, cracks and chips. There are super durable varnishes in this group, but their price is not encouraging.

Dispersion varnishes are better in this regard. One-component and two-component. One-component ones do not smell, but take a long time to dry. The two-component ones are very smelly when applied (use only with a respirator), but dry quickly.

Parquet primer and its features

To coat parquet with varnish, first use a primer and then a varnish. The type of primer depends on the base of the varnish. It is better to take formulations from the same company and there will definitely be no problems with compatibility. The parquet is primed twice. It is faster and easier to work with a roller with a long handle.

The primer prepares the wood for application of varnish, evens out its absorbency and reduces it

After the first layer of primer has dried, we check the surface. If the wood fibers have “raised” and the floor is very rough, take a sander, a 100 or 120 blade (preferably 120) and sand it until smooth. After applying the second layer of primer, we repeat the test. Individual rough areas may appear where intensive sanding was done. We polish them too. If the sanding surface is large, it is better to coat it with primer again.

How to apply varnish to parquet

Apply varnish to the primed parquet. Again, it’s faster to work with a roller, but using a brush is not prohibited. Some types of varnishes have a viscous consistency. After application, the surface is not smooth, but with small “craters” from the roller or stripes from the brush. Let the first two layers be like this. Before applying the top coat, add a little thinner to the varnish. It is chosen depending on the type of varnish. Do not pour too much, so that the consistency is a little thinner than the “standard” one.

Varnish, wax or soap are all possible options.

When covering parquet with varnish, it is better not to rush and carefully maintain intervals. It is strictly prohibited to begin applying the next layer before drying. The varnish must be applied evenly, distributing it well over the surface. Puddles and spills must be cleaned up immediately. If after drying defects are found - drips, drops - they are removed by grinding. 150 grit sandpaper or finer. Before applying the next layer, the dust is removed and the next layer of varnish is applied.

The correct base for parquet boards

You should not save money and lay the boards on an unleveled base: movements on them will be accompanied by creaking or crunching, since under the influence of the load the floor will begin to rise and fall. Over time, the locks will become loose and cracks will appear that cannot be eliminated. The base must be flat, the maximum horizontal deviation of the surface is 2 mm with a length of 2 m. The permissible size of “clearances” under the two-meter level lying on the base is no more than 2 mm. The strength of the screed and subsequent thin layers of finishing leveling is extremely important.

With the glued flooring method, plywood can come off from the fragile base along with its top layer, which will disrupt the stability of the floor structure. The destruction of the fragile leveling layer under the floating floor will lead to the formation of low spots and air pockets where cement dust accumulates. When moving along the floor, it will penetrate through the gaps near the baseboards into the living space. Thus, the standard requirements for the base—flat, strong and dry—are fully justified. And the masters of professional finishing teams will recommend the optimal installation method for each specific case.

Related link: Options for laying parquet with your own hands

METHODS OF LAYING PARQUET BOARDS

| OPTIONS | FLOATING METHOD | GLUE METHOD |

| Preparing the base | Standard | More thorough |

| Flooring area | Maximum area without the use of additional expansion gaps - 12 x 20 m | No limits |

| Installation | Quick and easy installation | Lengthy, complex and expensive process |

| Ready floor for use | Immediately after installation | The floor can be walked on 12 hours after installation; working loads are permissible after the glue has completely cured (after one to seven days depending on the type of composition) |

| Features of operation | Strong fluctuations in temperature and humidity are undesirable | Large fluctuations in temperature and humidity are acceptable |

| Possibility of floor removal | Eat | No |

| Possibility of floor sanding | No | Eat |

| Coating service life, years | 15-20 | 20-30 |

In modern apartments, we usually deal with concrete foundations and the problem of their excess moisture after completion of construction work or during operation. This question is relevant, for example, for monolithic houses, where the load-bearing structures are placed outside and are practically not thermally insulated.

As a result, the layers of the base of the floor near the external walls cool down, and a dew point forms at the border between the decorative coating and concrete/plywood and condensation appears. The humidity level is low, but periodically appearing moisture penetrates the concrete and flooring, which is why the latter inevitably begins to deteriorate. Therefore, we are for any option for a layer between a wooden floor and a concrete base, but we consider the best to be laying parquet boards (regardless of the flooring method: gluing or floating) on moisture-resistant plywood. This material functions like a sponge: it accepts moisture, but does not transmit it further; in addition, it retains its strength characteristics.

Related link: How to lay parquet boards with your own hands (click and lock systems) (photo)

How to care for the package?

All types of parquet require intensive initial care , and parquets coated with natural oil require treatment after installation. Oiled parquet requires more intensive care; it is slightly more expensive than varnished parquet, but is more durable and looks more natural.

For regular maintenance of oiled parquet, a broom or vacuum cleaner is sufficient. Only if necessary, the parquet can be wet cleaned, but only with a slightly damp cloth. It is recommended to treat parquet floors coated with natural oil once a year with oil. The properties of the oils used are different; before purchasing, you should study the manufacturer’s instructions and consult with the seller.

Direct contact of water with parquet is unacceptable.

Tips and tricks

- all work must be done correctly, take your time and be careful;

- it is necessary to prepare in advance for laying parquet boards - choose a laying method, direction, draw a diagram, buy the necessary material and tools;

- for more reliable adhesion, use properly selected glue;

- It is not advisable to install parquet at the beginning or end of the heating season;

- the parquet must get used to the climate of the room in which it will be installed, so before starting installation you need to give it 48 hours to just lie in the room;

- if the adhesive method was used, the floor should dry, and subsequent work should be done after a week;

- parquet must be chosen from well-known manufacturers;

- You should not carry out wet cleaning frequently, parquet is afraid of water; you can simply use a vacuum cleaner or a well-wrung out rag.

- professionals do not recommend laying parquet on a water floor, since if pipes break, the parquet can be severely deformed. A reliable design in this case is an electric or infrared floor.

- Removing various stains: blood can be removed with a damp cloth;

- black stripes from shoes are removed with nylon;

- The wax stain must be frozen, then it is removed with a plastic spatula.

To learn how to lay parquet with your own hands, see the following video.

Sources

- https://sdelatpol.com/naturalnye-pokrytiya/parket/kak-vybrat-shtuchnyj-parket.html

- https://pol-exp.com/preimushhestva-parketa/

- https://chudopol.ru/ukladka-parketa

- https://pol-exp.com/kak-klast-parket/

- https://dekoriko.ru/parket/ukladka/

- https://www.idealdomik.ru/yenciklopedija-poleznyh-sovetov/v-dom-prish-l-remont/parketnye-poly-raznovidnosti-parketnyh-polov-ukladka-parketnogo-pola.html

Styling design

There are several options for laying block parquet. The most popular are the following:

- Standard Christmas tree.

- Classic deck.

- Mosaic.

- Square.

- Diamond.

- Variant of the Sheremetyev Star.

Important! In fact, these methods differ from each other only in design, but the technology is approximately the same. The only thing is that you always need to keep the installation scheme in mind. Therefore, if you are doing something complex, then just print it out on a piece of paper.

Deck

This method is a classic version of laying parquet - each of the subsequent rows is shifted relative to the previous one by half the length of the plank. This scheme gives the surface strength and a beautiful appearance. As a rule, the planks begin to be laid along the wall, which is located opposite the entrance, and gradually move towards the doors.

Important! If you want the top layer to be glossy and almost monolithic, then lay the parquet along the incidence of the sun's rays. If you need to emphasize the design and structure, then across it.

The installation process is quite simple and looks like this:

- Lay the material along the wall, not forgetting to leave a gap of 10 mm. If the last board does not fit entirely, then saw it off and put it in place.

- Start laying the second row offset by half the length of the board (following the principle of brickwork). To connect, simply insert the tenon into the groove at a 45-degree angle and gently lower the board, tapping it with a rubber mallet if necessary.

Important! Try to check each joint, shaking the planks a little and pushing them into place until you hear a characteristic click.

- Continue laying the rows, each time moving left and right relative to the previous layer, being sure to remove the tenons from those planks that touch the wall.

Important! It is worth remembering that the deck laying method can also be diagonal. If you are going to lay the parquet this way, then you should draw diagonals from the center of the room at an angle of 45 degrees and lay the parquet parallel to them, starting from the corner farthest from the entrance. This method is more labor-intensive, and in addition, to implement it you will need 10% more material.

Standard herringbone

To lay parquet with your own hands using this method, it must have tenons on two corner sides and grooves on the other two. You need to be careful not to mix up the strips - the connecting grooves should always lie in the same direction. Here, standard installation at an angle of 90 degrees or a modernized installation at an angle of 45 degrees is allowed.

In order not to make mistakes regarding the installation picture, you should lay two rows along the walls. As a result, you will get a visible drawing and a straight line, relative to which all the work will subsequently proceed. To keep it flat in the future, pull a string on two weights and self-tapping screws.

Important! It is advisable to lay herringbone parquet with glue, since it does not have the same strength as deck parquet. In this case, you will not need locks - you can simply cut them off.

Squares, diamonds, stars, braids

These methods of laying parquet boards can be combined into one. For them, you will definitely need a diagram so as not to get confused.

Important! It is best to lay the boards using glue using this method.

The installation principle is quite simple:

- One pattern is assembled entirely (square, star, diamond).

- After that, they move from this element according to the chosen scheme.

- After each row, the pattern is shifted to create a dressing.

Important! There are a lot of layout options with this method, so you can choose the one you like best. For such parquet patterns you will need more material than with classic ones, so you should take this fact into account when purchasing.