Country holidays have long become a good tradition for many people. Those who have suburban areas try to pamper themselves with outdoor recreation in the company of friends and loved ones at least several times a year. Such memories are the warmest and last for a long time.

What vacation outside the city would be complete without barbecue? Fragrant, fried meat is an integral part of country leisure. To prepare this dish, you will need a grill. Of course, now there are many different models that are distinguished by their quality and reliability, but if you are interested in original products that are not like all the others, then today we will figure out how to make a barbecue from a barrel with your own hands.

Pros and cons of homemade structures

A barbecue made from scratch from a metal barrel will allow you to fry excellent kebabs, steaks, sausages, chicken, fish, bake potatoes, cook food in pots and much more. The main advantages of this solution include:

- Easy metal cleaning, repair and low maintenance.

- Using such a barbecue is safe and practical. Welding work is carried out independently.

- The metal holds heat remarkably well, so the meat is effectively fried.

- The price of materials is minimal, any budget can handle it.

Barbecue from a barrel

Barbecue from a small barrel

The disadvantages of such a device are:

- Instability to corrosion.

- Rapid heating, which can result in burns.

- The one-piece design does not allow it to be transported over long distances.

What tools and materials are needed

Many summer residents have often wondered how to make a barbecue out of a barrel with their own hands. Having a barrel is only half the battle. In addition, you should worry about additional materials and some tools in advance. To create a full-fledged barbecue you will need the following equipment:

- Bulgarian;

- electric welding;

- metal cutting disc;

- gloves and safety glasses;

- roulette;

- marker;

- electric drill;

- spanners;

- hammer;

- drills, screwdrivers;

- drill;

- grinding disc.

Barrel in the form of a barbecue

To build such an original structure, you will also need main and additional materials:

- empty metal barrel of the required size. Often, to make a barbecue with your own hands, they use 200-liter barrels, but other options are possible;

- door hinges;

- bolts connecting parts;

- metal corners 20x25;

- door knob;

- steel tape;

- stainless steel mesh;

- fasteners;

- profile pipes;

- for mobile movement of the structure, you can use 4 wheels;

- special paint;

- cooking temperature regulator.

Step-by-step instructions for making a barbecue

A brazier from an iron barrel can be made in one of the following ways:

- From two cut halves. The design allows for convenient access to the entire internal space, but reduces wind protection;

- With cutout for lid. It protects the internal volume from precipitation and wind, retains heat from the coals longer, but reduces the ease of access to the prepared products.

Brazier from a 200 liter barrel: step-by-step instructions for making from two cut halves

Creating a barbecue or barbecue from a barrel with your own hands is carried out according to the following step-by-step instructions:

- We thoroughly rinse and clean the metal barrel from substances stored in it and from external contaminants. To do this, we use cleaners and solvents on the outside, and first water and then solvents on the inside.

- Mark the cutting lines. To do this, use a tape measure to measure the circumference of the base, divide the resulting value in half, then plot the calculated length on it from the starting point. We connect the starting and delayed points with a straight line using a marker. We draw straight lines along the side walls perpendicular to the plane of the base to the opposite side of the barrel. Using a marker, draw another cutting line connecting the two side points.

- We fix the barrel in a stationary state and saw it with a grinder along the markings. Be sure to use personal protective equipment: gloves, goggles and thick clothing. It is important to make a neat cut, since the second half can later be used to refine or change the design being created, or for a new barbecue from a barrel.

- We cut out the edging for the barbecue from the steel corners. The dimensions of the sides are as follows: the length is equal to the length of the container plus double the width of the corner shelf, and the width is 8-10 cm less. That is, you need to cut 2 long and 2 short corners. We make the ends straight or at an angle of 45 0 for subsequent welding, taking into account the fact that the long shelves should be directed towards the inside, and the side ones towards the outside.

- Using a welding machine, we weld the edging and get a single frame.

- We place half the barrel in the edging and check the tightness of the fit. If necessary, use a grinder to carefully clean the ends of the edging. It is strictly prohibited to file the container itself.

- Using an angle grinder, we cut out the pipes according to the external dimensions of the length and width of the edging so that it is possible to weld them securely to each other and insert the edging into the frame. The long parts of the two structures will touch the side surfaces, and the end angles will be inserted into the pipes.

- We weld the pipe structure.

- We check the fit of the edging in the frame.

- We cut legs for the frame from pipes. Their length is selected taking into account the height of the person who will cook the kebab in the grill. Usually it ranges from 0.8 to 1.2 m. We cut the ends at an angle of 15 0 so that their planes are parallel.

- We weld the legs to the frame with the spread outward. This will increase the stability of the structure.

- We take a steel strip and make additional supports for the container. To do this, we bend it along the diameter of the barrel, and then cut it to length so that it can be welded to the edging.

- We weld the edging to half the barrel.

- We weld the supports to the edging.

- We check the fit of the barbecue into the stand body.

- Along the long parts of the container, using a grinder, we cut recesses opposite each other for the location of skewers.

- We weld steel handles at the end parts.

Instructions for making a barbecue with a cutout

If the first option takes a lot of time to make and you have difficulties with it, then don’t despair, since making a barbecue with a cutout from a barrel is much easier and faster.

To do this you will need:

- Rinse and clean the barrel.

- Mark the cutting line. To do this, it is necessary, at a distance of 5-10 cm from the end parts, to draw a line with a marker 1/3 of the length of the circumference of the barrel parallel to the base on both sides, and then connect their ends along the side walls.

- Use a grinder to cut out the marked area.

- Attach the cut part to the barrel using two rivet loops.

- In the side parts of the grinder, cut parallel thin holes in the place where the coals are kindled with a length of 8-12 cm and a width of up to 3 mm.

- Make a stand for the barbecue using the method described in the instructions above, or make only the support legs from pipes and weld them to the ends of the barrel.

- Weld the handles on the sides of the grill.

- Make slits in the body for laying out the skewers.

- On the side opposite to the opening of the lid, you need to weld a hook to fix its position.

To make a barbecue from a barrel with your own hands, you need to change the drawings slightly: inside you should weld shelves from steel corners to install the mesh. This results in a design that is universal in use.

The final stages of processing the finished product: grinding, firing, painting

At the first stage of processing the structure, it is necessary to perform firing to remove decorative coatings, remove or neutralize traces of substances stored in the barrel. Take a rag, soak it in diesel fuel or gasoline, lay it out in an even layer on the grill and set it on fire.

After the rag burns out, we begin sanding the surface. To do this, use a grinder with a grinding disc attached to it to remove the surface layer from all metal parts of the structure. The result should be a shiny, smooth surface.

At the third stage, clean the surface to be painted from shavings and dirt, use a soft rag soaked in alcohol. When the surface is dry, apply several layers of paint using a spray gun.

Upgrading a barbecue from a barrel to a smokehouse

If a barbecue was made according to one of the instructions, the barrel smokehouse can be easily modified and a universal design obtained. The finishing touches include equipping the barbecue with an opening lid made from the other half, with the installation of two chimney pipes. If the design was carried out according to the second instructions, then you will have to cut two chimneys into the lid.

The longer the pipes, the higher the draft.

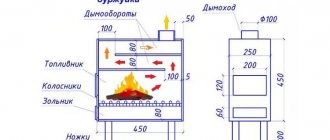

Where to start the manufacturing process

The first thing to think about is the type of model you would like to get. The most convenient way is to draw a sketch of the selected option. Next, to create a barbecue from a barrel with your own hands, drawings are drawn up, for example, as in the photo.

Diagram of one of the simple models

Drawing of a complex barbecue

The provided drawing is just one of the possible options. The diagram should indicate dimensions that can be easily calculated taking into account the parameters of the barrel. This will help you not to be distracted by measurements and calculations while working.

Then we proceed to manufacturing the required parts, these include:

- pipes and angles of the required size;

- the required number of hinges, bolts, screws and other parts, according to the drawing.

Before starting work, you need to make sure that the barrel is completely empty and does not contain flammable or other harmful liquids. If necessary, it should be washed so that it does not ignite while using the welding machine. Metal containers for fuel and lubricants of 200, 100 or 60 liters are often used for barbecues.

The barrel is placed in an elevated area and secured securely, then the paint is removed from the surface. For this, a stiff brush is used or the process is carried out using a grinding unit with a flap disk. The paint removal procedure must be carried out, otherwise when heated it will bubble and create inconvenience.

Removing paint

Coloring rules

After all welding and assembly work has been completed, we can move on to the appearance of the unit. Considering that the grill will be exposed to fire and smoke during operation, we will choose a dark color for the entire structure. Usually black color is used. So that the paint can prevent corrosion for a long time, we carefully degrease all surfaces of the grill. Only heat-resistant paint should be used. It is best applied using a pressurized spray bottle.

To ensure the quality of the surfaces being painted, three layers should be applied.

After the paint has dried, the unit is ready for use. All that remains is to fill it with food, firewood or coal.

Those of us who are the happy owners of a summer cottage have probably thought about installing a barbecue more than once. There are a great many designs of kebab makers that you can assemble yourself. Which one should you choose? As a rule, a barbecue grill and a barbecue roaster are combined into a single unit so that different types of food can be cooked in one go. If your goal is to get by on a minimal budget and at the same time get a comfortable and durable barbecue, then pay attention to a kebab maker made from a barrel.

How to cut a barrel correctly

The next stage is to work with the main structural part - the barrel. This is a very important point in the manufacturing process. The further quality of the entire structure depends on the evenness of the lines and the uniformity of the cut. Before starting work, use a tape measure and a marker to mark the cutting lines. If necessary, remove the barrel from the raised platform and then secure it back in place.

Brazier with hinged lid

First cut option:

- Using a grinder, only part of the container is cut out, which will later serve as a lid. Its size should be 1/4 of the circumference of the barrel.

- Leave 2-5 cm on each edge.

- The edges of the cuts are cleaned and the unevenness is smoothed out.

- After the work has been completed, the dimensions and configuration of the corner for finishing the cutout are determined.

Cut out part of the barrel

Second option:

- You can make a barbecue out of a barrel with your own hands, as seen in the photo, from a barrel cut in half, creating two identical parts.

- From the halves you can make two full barbecues or one in which one part will serve as a lid.

- A door handle is attached to it, and door hinges connect it to the main part.

- The result is a grill with a lid.

The barrel is cut in half

How to choose and properly prepare firewood for a barbecue

Experienced connoisseurs know how much firewood affects the taste of dishes cooked on a barbecue or grill. Firewood from fruit trees - pear, apple, cherry, apricot and other stone fruits - has the best properties. They have fairly dense wood that retains heat for a long time and gives the meat a unique aroma. Pine and spruce firewood is not suitable. Their wood contains a lot of resins, which during combustion release toxic substances that can not only spoil the taste of your favorite dishes, but also harm your health.

Firewood for barbecue should not be very thick, but not thin either, since thin logs do not retain heat well. And in order for the heat to be uniform, they should be split into bars of equal thickness. This is not always possible with a regular axe. A manual wood splitter “Kolundrov” will cope much better with this task - it is an excellent tool for simple and safe chopping of firewood. With its help, you can easily chop wood of the desired thickness without any effort. It has an aesthetic appearance and a safe design that protects against accidental injury. It will also be a great entertainment for you and your guests, giving them an unexpected WOW effect.

How to make a grill with a cutout

After the barrel is cut, a chimney is made. For this purpose, steel pipes with a diameter of 70 mm are used at an angle of 45°. Connect both sections of the pipe in the form of an elbow. The joint is carefully welded to eliminate the possibility of gaps.

Chimney from a pipe

The inside of the grill barrel is finally cleaned. For this, special microwave oven cleaning products are used, especially if the walls inside were full of liquid oil.

Since the size of the barbecue stand depends on personal preferences and the size of the barrel, you will have to make it yourself. It is made from a profile pipe with a rectangular cross-section. The frame is made folding and consists of two rectangles.

The size of the pipes should be comparable to the volume of the barrel (for example, for a 100 l container - 20x30 mm, and for 200 l - 30x50 mm, respectively). Frames are welded from pipes, one of which is slightly larger, and the second is smaller (fits inside the first). The frames are secured with a bolt in the center (the bolt is used as a hinge). A washer is placed between the frames to create a gap.

Barrel stands

Then a piece of the barrel is installed, which will serve as a lid on the main part, and with a marker, the places where the door hinges will be attached are marked. Next, using bolts and nuts, the hinges are attached first to the lid and then to the main part of the grill. To prevent the lid from falling inward during use, a steel strip is welded to it on the sides.

Attaching the hinges

Then a voluminous door handle is attached to the barbecue from a barrel, or it can be welded from a profile pipe, as in the photo.

Grill lid handle

To hold the grate, several steel wires (8-10 mm in diameter) are installed across the entire barrel. On both sides of the bottom row, the wire should protrude 8 cm from the end of the barrel wall. By welding a piece of similar wire between them, you can get handles for installing or moving the barbecue.

Order of placement of steel fasteners

A round hole is cut in the upper part of the side wall of the barrel to install the chimney. Holes are made at the bottom of the cylinder for ventilation. Smaller holes are drilled in the middle of the grill for drainage. If you want to install a temperature regulator, you will need another hole in the lid for mounting.

Additional holes

A hook is attached to the back of the lid to secure the two parts in the open position. This is a very necessary device that will allow you to safely use a barbecue from a barrel. After all, it will be blocked.

Hook-locked lid

Manufacturing stages

- Washing the barrel. Before sawing the barrel, you need to remove any remaining solvent from it to prevent an explosion. To do this, pour a full barrel of water and pour it out immediately. After this, it is recommended to leave the barrel in the sun to allow any remaining solvent vapor to escape.

- Using a tape measure, measure the circumference of the barrel. The result obtained must be divided by 4. The resulting figure is the distance that must be set aside from the traffic jams in order to find two opposite points on the base of the barrel, equidistant from the traffic jams. We mark these points on both sides of the base with a marker, draw two straight lines connecting opposite points of the cylinder along the surface of the barrel.

- Using a grinder, carefully saw the cylinder in a circle. Don't forget about safety glasses. We cut against the direction of the cutting disc so that the grinder does not get bitten by the metal and is torn out of your hands.

- Let's move on to cutting the edging of our future barbecue. We will make the edging from the corners. We measure the corner along the length of the sides of the barrel section. You should get 2 long and 2 short. Conventionally, we saw the upper part at 45 degrees, the lower part at 90.

- We use a welding inverter to weld all 4 corners into the edging, after which we try on half the barrel to fit it in size.

- The legs of the future design are cut from a square pipe, length 900-950 mm. We saw off one side of the leg at an angle of 15 degrees so that there is a slight spread of the legs for better stability.

- We insert the legs into the space between the base of the half-cylinder and the frame of the corners, mark with a marker the intersection of the edging of the barrel.

- Using a grinder, we cut out the edging so that the leg fits close to the barrel.

- We collect all the elements and weld them together.

- Steel tape 25 mm. we will need to make guides for a mobile support from skewers. We measure the tape according to the inner width of the future grill and cut it off. You need 2 guides and they should be located along the edges of the grill on the inside. We put it in place and weld it.

- We make the mobile support for skewers from a corner. To do this, we measure one shelf of the corner along the outer edges (along with the frame) of our barbecue, and the second along the internal space between the guides. Using a grinder, we cut out a rectangular piece from one shelf of the corner.

- Our next step is to give the future device for cooking kebabs a marketable appearance. To do this, insert a grinding disc into the grinder and remove all the irregularities and welds. The entire structure, as a result of the grinding process, should be smooth, glossy and shine in the sun.

- From a ten-millimeter tape we bend a poker that is slightly longer than the width of the future barbecue.

- Removing rust and dirt from the surface of the barrel, in this way we prepare it for the next stage - firing.

- Burning is necessary in order to remove paint from the surface and degrease it before applying paint. We will burn it with diesel fuel prepared in advance for this purpose.

We take a rag, moisten it with diesel fuel, and use it to apply diesel fuel to the surface of the barrel. Then we set fire to the rag. To make your task easier, use fire starter or ethyl alcohol. Just splash a little alcohol on the burning rag from afar. Next, we wait until all the diesel fuel burns out and the paint peels off the barrel. Even if paint stains remain here and there, it’s okay, the fire destroyed all harmful substances.

- Our next action will be to wash the grill from soot and soot. A Karcher car washing machine is perfect for this purpose.

- Using an electric drill, drill holes in the bottom of the grill for paint drainage.

- Using a spray gun, apply heat-resistant paint to all structural elements. It is advisable to apply the paint in several layers so that it applies evenly. The paint dries at a temperature of 23-25 degrees during the day.

It is not recommended to make blowing holes in a homemade grill, as the coals will be hotter and will smolder longer.

Brazier made from two halves of a barrel

The principle of constructing a barbecue with a lid is practically no different from the option described above. But in this case, it is necessary to frame the edges with a metal corner, which can be attached by welding or screws.

The hole in the barrel is used to install the chimney. You need to try to ensure that when building a barbecue it is in the upper part. This model, when installing special racks, is quite suitable for placing grill spits.

Grill mounts

You can buy a grill grate in a store, or you can use a stainless mesh for this. Instead of steel wire, parts specially made from steel tape are also used to secure the grill, which are attached to the bottom edge of the barrel.

There is also a second option for creating a barbecue from a barrel cut in half. It uses only half a barrel, or two barbecues can be made from one barrel. You can learn more about creating a grill without a lid with your own hands from the video.

Do-it-yourself barbecue from a barrel - stages of construction

To work with a metal container, you need to use chalk to draw a hole in the shape of a rectangle on the surface from the outside. But before this, the barrel is placed on a frame prepared in advance so that the drain hole is located on top at an angle of 30 degrees. This is necessary so that in the future an exhaust pipe can be connected to it to remove smoke.

The outlined part will subsequently be used to cover the structure. The lid is carefully cut out along the outlined contour with a grinder, and the edges are cleaned with a grinding wheel.

. After this, door hinges are attached to the barbecue body, which are connected to the lid with bolts. The sides of the barrel are drilled to ensure good traction. At this point, the external work with the barrel can be considered complete; all that remains is to attach the handle and connect the drain hole to the curved metal chimney.

In addition to exterior work, you also need to work on the interior of the structure.

. To do this, measure the length of the barrel and cut 2 metal corners of the appropriate size. Cuts are made on the corners in increments of 7-10 cm and the blanks are welded to the inside of the barrel. They will serve as a support for placing skewers with meat on them.

At the final stage, to give the structure an aesthetically attractive appearance as in the photo, it must be painted with heat-resistant paint. There is no point in considering any other dyes, as they will simply fade. After the structure has completely dried, the barbecue made from a barrel, made by yourself, can be used for its intended purpose. Despite the fact that the process of manufacturing a device for frying meat on coals is quite simple, it requires skills in working with electric welding.

Barbecue with smokehouse function

Only at first glance this design seems very complicated. To create it you will need two barrels. The grill and smokehouse are made exactly according to the diagram. The most difficult part of this process is connecting the two containers together and making a door at the bottom for adding firewood.

Scheme for making a barbecue with a smokehouse

The device is original, but not very practical, since it is rare to use a barbecue and a smokehouse together. And heating the structure is very difficult. Therefore, it is better to make them separately and removable, using the same stand for installation.

Barbecue and smokehouse

Painting the grill according to all the rules

To give a barbecue from an old barrel a more aesthetic appearance, it should be painted. To do this, thoroughly degrease the surface and cover it with a heat-resistant coating, which include:

- Silicone enamels that can withstand temperatures up to 600ºC.

- Thermal powder paints are suitable, but they are quite difficult to use at home. These paints require high temperature firing.

- Oxidation is a rather complicated procedure, but it can be done even at home. The grill parts are degreased with sulfuric acid. Next, they are boiled in a soap solution and boiled in a sodium solution for 1.6 hours. After which the product is coated with a non-stick layer that can protect the metal from corrosion.

Also, any inventive barbecue owner can install various shelves on it at his own discretion. This will make the cooking process more comfortable, and will give a barbecue made from an unnecessary barrel a more homely look.

Option with shelves

A barbecue made from a metal barrel will be an excellent tool for making barbecue. During use, you can come up with many other functions, you just need to use a little imagination, and you will delight your family and friends with wonderful food made in the fresh air.