Any builder will be able to say that preparing a solution manually in any container with a shovel or hoe is extremely difficult, especially when you need a lot of it, therefore, a concrete mixer, assembled with your own hands, can be an alternative to manual labor and a factory unit. Of course, a home-made mechanism must compare favorably in cost, otherwise there is no point in it - it’s easier to rent it or buy it in a store.

Do-it-yourself concrete mixer from a barrel with manual drive

Therefore, the component elements of the mechanism should be, as they say, “at hand,” and the device itself should be as simple as possible. Now we will try to assemble a design that is accessible to any home craftsman, and we will also watch the video in this article, which clearly touches on our topic.

Device requirements

Using a concrete mixer when building a house

There are several options for making concrete mixers. They can be:

- Simple, working due to the application of human effort.

- Using an electric motor.

- Collected from improvised means, with your own hands.

In any case, the design must satisfy certain requirements. These include:

- Safety at work. This is especially important when using an electric drive.

- Low cost, easy to manufacture. The components for assembling the structure, and the assembly itself, should not be expensive.

- Ease of use.

Drive on a concrete mixer

How to make a hatch for a concrete mixer: design nuances

When you cut out the loading hole in the barrel, you will have a hatch and a door that needs to be secured so that it is convenient to close it and unload the solution.

In order to load materials without loss and unload the solution into the prepared container, you need to make a metal box along the chute around the loading hatch

To prevent the manhole cover from falling into the barrel, two metal strips 2–3 centimeters wide need to be welded along the edge

Strong and hermetically sealed fixation of the manhole cover is guaranteed due to pipes welded on four sides. After loading the solution materials, the fixing bolts are screwed through them

Composition of a concrete mixer and manufacturing tips

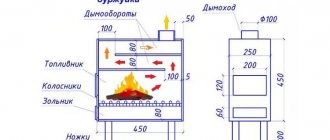

Concrete mixer design diagram

Before you make a concrete mixer with your own hands, you should get acquainted with its main components and listen to the advice of experts.

Advice: A newcomer to welding, who knows about it only by hearsay, should not start making a concrete mixer with his own hands, but entrust all the work to a person familiar with this matter.

Next you need:

- Assess the profitability of the future design. If you need to purchase all the parts, it will most likely be cheaper to purchase a ready-made model.

- Have experience in design.

- Prepare all the necessary materials, preferably at a minimal cost.

- Have a great desire to make a concrete mixer with your own hands, despite the complexity of the design.

When considering any design, we can distinguish three main parts:

- Tub or drum. At the same time, for mechanical or combined methods, a cylindrical container is not very suitable for mixing components, due to poor mixing of the solution in its corners.

This can be avoided, but you will need human help to mix the solution manually or increase the mixing time, and this will lead to additional energy costs.

Tip: To improve the quality of concrete, the concrete mixer tub should be positioned horizontally and a comb mixer should be used.

It is best to round the tub, giving it the shape of a pear or egg. If the volume of solution is small, you can use two metal or plastic basins instead of a barrel, but only if the unit will operate very rarely.

To do this: the bottom of one basin is cut out, the neck of the container is strengthened with one or two strips fastened crosswise. Such a structure can only be installed at an angle; side unloading will not work.

- Drive unit. It is impossible to make a concrete mixer with a gear rim on the body, as in ready-made branded designs, at home, and it is quite expensive to purchase, but this unit can be replaced. To do this you need to have:

- From a car engine - a flywheel.

- Gear bending.

- Wheel hub.

According to the first option: one end of the drum axis enters a sleeve with a ball bearing located inside the hub.

The flywheel and container will rotate around the axis. According to the second option: the hub is welded to the flywheel, and the drum is attached to the hub at the rear bottom. In this case, one coupling is fixed to the flywheel, and the second is installed to strengthen the neck.

After positioning the container at an angle, the upper bearing of the structure will be filled with concrete. This option is best used when the drum is located in a horizontal position, with side discharge of the finished solution and a solid bottom.

Tip: If you have a gearbox with the required gear ratio on hand, it can be used for a concrete mixer by connecting it to the axle. For a tank located at an angle, a gearbox with spur wheels is used; for horizontal installation, helical gears are used, with an optimal rotation speed of up to 50 rpm.

The drive for the structure can be adapted from a walk-behind tractor, as in the photo.

DIY concrete mixer from a walk-behind tractor

Do-it-yourself concrete mixer for a tractor

- Mixer. What location of the mixer the concrete mixer has on its own is not very important. For barrel construction and similar containers, the assembly is welded to the axis. An exception is the attachment of a comb mixer.

After getting acquainted with the main components of the structure and choosing a method for mixing the solution, you can begin assembling the concrete mixer with your own hands; the video will tell you how to do it correctly.

How to make stable supports for a concrete mixer

The supports perform two functions: they hold the barrel weighted with mortar and are the basis for the rotation mechanism.

The top of the A-shaped structure is crowned on each side with pieces of a profile; bearings are located inside them to ensure rotation. All these parts can be assembled by welding and additionally reinforced with metal corners

Do not waste time and material on assembling the base. It is necessary to make not only a support connecting the perimeter, but also several slopes, as well as reinforcing crossbars at the bottom and top of the structure

Preparing for the manufacture of a concrete mixer

Before manufacturing the structure, it is necessary to make a drawing or sketch of the future product, prepare the assembly site: supply electricity, ensure that noise and dirt do not enter the residential building or plant beds.

Drawing for making a concrete mixer

Tools you may need:

- Welding machine.

- Electric drill.

- Screwdriver Set.

- Hacksaw for metal.

- Capacity.

- Rolled metal for making a frame.

- Select a motor with a power of at least 1.3 kW.

- Metal for blades used when mixing components.

- If this is a do-it-yourself auger concrete mixer, you will need to select or make a screw shaft.

At the stage of preparation for work, it is necessary to decide whether the concrete mixer for pouring the foundation with your own hands will be on wheels or stationary. After this you can start working.

But for better assembly of the structure, solving all the questions of how to make a concrete mixer with your own hands, the video will provide undeniable help.

Making a manual concrete mixer

Sketch for assembling a simple concrete mixer

The do-it-yourself mini concrete mixer shown in the sketch can be made from materials that can be found at any owner of his site. Wherein:

- The container can be an old barrel, closed on both sides with lids, or a large diameter pipe with ends welded on both sides. A hole is cut in the center, along the length of the barrel, for loading components and unloading the finished solution.

- Holes are drilled at the centers of both ends for the existing pipe, which will serve as the axis of rotation of the container.

- For greater structural rigidity, flanges are welded or screwed to the ends, the inner diameter of which is made with a small gap of up to 0.5 mm with the axle.

- A comb is bolted or welded inside the barrel, which improves the mixing of components to obtain a solution.

- The axle with the drum is mounted on supports. They can be assembled from channels or corners that are available.

- A bracket with a handle is attached to the end of the axle.

Manufacturing a concrete mixer with a drive

Drive on a concrete mixer

A large do-it-yourself concrete mixer is made with an electric drive.

The instructions for its assembly suggest the following procedure:

- A frame with a barrel for the future unit is being assembled. It must be strong enough due to the large load on the base. Wherein:

- The frame should be made from a profile corner with walls of at least 130 mm.

- Bolts with a diameter of 27 mm are used to fasten the elements.

- The barrel is installed at an angle of 35°.

- To transmit torque from the engine to the barrel, a ring gear is attached; it can be used from a Volga car engine, welded or bolted.

- The gearbox is mounted on the frame.

- The barrel is installed. The inside of the drum can be filled at your discretion or you can use the same design as for a manual concrete mixer.

- To make foam blocks, assemble a concrete mixer for foam concrete with your own hands. Its difference from concrete mixers is the presence of a special mixing device.

DIY foam concrete mixer

- A steering wheel is attached to tip the barrel.

To make a concrete mixer of any kind with your own hands, for greater clarity of the assembly work, it is worth watching the video in this article.

Some tips for operating the equipment

The assembled structure, like any equipment, requires compliance with the operating rules:

- Do not put your hands into the rotating drum.

- When connecting electricity, you need to ensure that the wiring is in good condition.

- Even when the unit is not working, children should not be allowed near it.

- When using a mobile structure, you should always put chocks under the wheels before starting work.

- Due to the high vibration of the drum, the connection of elements in units that require periodic tightening of fasteners may be disrupted.

- Never leave switched on equipment unattended.

Making even the simplest concrete mixer with your own hands greatly facilitates the hard work associated with the use of concrete mortar, saving not only effort, but also human time.

What is needed to assemble a concrete mixer

The main thing in creating such a device is a suitable container for the solution. The best option is a used two-hundred-liter barrel. You can find it through private advertisements or at a scrap metal collection point. The barrel must be intact, without damage.

In addition to this container, you will need bolts, several pieces of sheet metal, cuttings of a round pipe and profile. If you plan to mechanize the device, you will need an automobile gearbox and a motor with a power of at least 5 kW.