In our time, many people do not always have good memories associated with the heating season, since during this period not every home can boast of warmth and comfort, regardless of the type of heating. However, in the memory of the older generation, there is a serious assistant in heat production. This is a so-called metal stove-stove, shaped like a barrel or box with a small door and pipe. The latter was most often displayed without any special tricks - through the window of the room.

This simple invention became an indispensable heating structure and saved the day when it was not possible to heat a real Russian stove or it simply did not exist. The potbelly stove was highly efficient - it only needed a couple of small birch logs to quickly supply heat to the room.

Such a stove from the past has not been forgotten to this day. It is used by builders, summer residents, garage regulars, and even residents of apartments that, for some reason, do not have enough heat in cold weather. This fact is not surprising, because this device can be easily made by yourself.

Advantages and disadvantages

Homemade long-burning wood-burning stoves have their advantages and disadvantages, like any other device.

Among the advantages are:

- high efficiency;

- economical fuel consumption;

- possibility of burning firewood, sawdust, wood briquettes, waste from wood processing companies;

- small dimensions;

- simple design that allows you to quickly make a stove at home;

- simple air supply control using a damper.

The disadvantages apply to both factory units and home-made devices. Among them are the need for the first firebox in normal mode and the complex design of the chimney. During operation of the stove, condensation is released, it settles on the inner surface of the chimney, and a layer of soot is placed on top. Therefore, the chimney must be made without corners or bends.

Before prolonged burning, the unit must be melted as usual. This will warm up the inside of the stove and the chimney. After the firebox, ash is removed from the ash pit and the device is set up to operate for 10-12 hours without additional wood fuel.

In this video you will learn how to make a long-burning wood-burning stove:

Do-it-yourself wood-burning garage oven: safety rules

A self-made potbelly stove for a garage must first of all be safe. When using it, the following rules must be observed:

- the floor and walls around the stove must be made of refractory material : tiles, iron, plaster, brick. It is permissible to cover the walls with special plasterboard;

- flammable objects or substances near the stove

- the stove can only be built from proven quality materials;

- the garage must be equipped with a ventilation .

A DIY garage wood stove Therefore, ventilation of a garage equipped with a potbelly stove is extremely important for two reasons:

- if there is a lack of oxygen, the fire in the stove will go out or burn weakly;

- Excess carbon dioxide indoors can cause poisoning or death.

To remove combustion products from the garage, it is necessary to install a chimney , but if problems arise in the pipe, ventilation will prevent the garage from catching fire or poisoning the people in it.

The necessary access to fresh air can be ensured by leaving a small (up to 5 cm) gap under the gate or by making several ventilation holes under the roof.

Do-it-yourself wood-burning stove for the garage:

Selecting a location

It is best to install a potbelly stove in the corner of the wall opposite the gate. The heat emanating from the far corner will warm the room and remain in the garage even when the door is opened. The distance from the wall to the stove can be about 0.5 m if the walls are made of brick, iron or any non-combustible material. With wooden walls, it is better to move the stove 1 m and cover the walls with bricks, tiles or cover them with a steel apron.

An iron sheet is placed underneath the stove or the floor surface is cemented within a radius of 1-1.5 m. Thanks to this, coals that accidentally fall out of the stove or flying sparks will cool down without causing a fire in the garage.

Design and Application

The main feature of the long-burning furnace design is its two chambers. In one, wood is ignited, in the second, gases are burned. In some models, the firebox is located in the upper part of the body, and the second chamber is located under it or through a partition. Combustion starts from the top layers of fuel, then the wood goes down. With the help of fans, new air flows are supplied.

Another option is to place one camera at the bottom and the second at the top. Pyrolysis gases rise into the upper opening without additional draft. The firebox volume of such stoves is smaller, but there is no need to install a fan.

Homemade wood-burning stoves are used most often for heating large greenhouses, garages, workshops or utility rooms. If you make the structure airtight and properly equip the chimney , you can place the unit in a residential building. In this case, you need to equip the device with a water circuit, which is connected to the radiators of the heating system.

How to make a homemade long-burning boiler:

Materials and tools

To make a homemade wood-burning stove, you need to choose high-quality materials and tools. You need to prepare:

- steel sheets, metal drum or empty propane tank;

- metal pipes for the pipe and chimney;

- Sander;

- Bulgarian;

- welding machine;

- grate of grates;

- drill with metal drills;

- ash pan;

- handles, doors and hinges.

When carrying out work, you need to protect your eyes with special glasses and wear a welding suit. It is better to cover all seams with sealant or alabaster cord.

The finished top combustion stove must be checked using sawdust. This fuel allows you to slowly warm up the unit body and check the correctness of all connections.

How to make a long-burning potbelly stove:

A little about fuel

The most environmentally friendly fuel for stoves are dry logs and firewood, as well as pellets - small chips and sawdust made by pressing dried wood.

What else can fuel pellets be made from:

- cones;

- seed husk;

- nut shells;

- dried citrus peel;

- wood bark.

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Barrel stove

Stove makers can make a small stove from old metal barrels of various sizes. The top of a larger container is cut off with a grinder, a thin strip is made from a steel sheet and attached to the lid, making it airtight. The handle is also welded. In the lower part you need to make an opening for the ash pan and insert a suitable metal box into it.

In a smaller barrel, you need to make a round hole in the bottom. The small body is placed in a large container on a triangular stand so that the opening is located above the ash pan. A hole for the pipe is cut in the side of the outer barrel. A short part is cut off from the pipe and welded to the body. Other sections of the chimney must be attached to this part at such an angle that it can be taken outside the room.

A homemade long-burning stove can be made from a barrel

You need to install a wooden log in the firebox, covering the hole in the lower part with it. Then sawdust is poured into the container and compacted. The fuel is poured with a small amount of incendiary fluid and set on fire. The structure is covered with a lid, and during the combustion process the gas is released into a large barrel, where it burns out a second time. The finished oven is installed on a car rim.

Long-burning supercharged stove

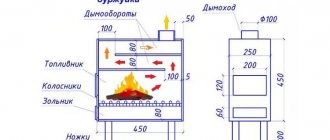

The wood-burning stove shown in the drawing consists of the following elements:

- horizontally located firebox with a volume of 50 liters;

- An ash pan equipped with a separate door is welded to the bottom of the firebox;

- vertical secondary chamber with chimney pipe;

- an inclined air channel laid through it;

- the third chamber with heat exchange fins and a heated air outlet pipe.

Note. The furnace in the drawing is shown in section. The method of joining two pipes is arbitrary, the internal passage hole is of square section, measuring 15 x 15 cm.

A fan is installed on the horizontal air pipe Ø100 mm, provided in the vertical part of the stove. A corrugated aluminum pipe is connected to the outlet fitting of the heat exchange chamber, pumping hot air into the adjacent room.

The operating principle of an iron stove is based on intensive heating of the air flow created by a fan. How the heating unit functions:

- Firewood 0.5–0.7 m long burns in the firebox; the amount of supplied air is regulated by the ash pan door.

- Combustion products penetrate into the second chamber, where pyrolysis gases are burned. Plus, heat is transferred to the outer walls and the internal inclined pipe. The spent volatile substances are then released into the street through the chimney.

- The air forced by the fan is preheated in an inclined channel, then enters the main heat exchange chamber located directly above the firebox.

- Having finally warmed up from the internal ribs and the hot arch of the firebox, the air flow exits through the vertical pipe and is directed to the adjacent room.

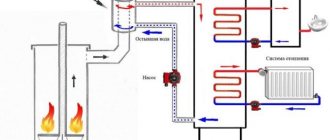

Vertical furnace with water circuit

This potbelly stove can operate on wood, coal and briquettes. The unit is made from one 50-liter cylinder installed vertically. Inside the upper part there is a heating chamber with heat exchange fins through which water or air flow can be driven. Let us briefly list the technical characteristics of the stove:

The principle of operation of the furnace is simple: the flame heats the side walls of the unit and the bottom of the upper chamber with welded metal plates. Water or non-freezing liquid is forced into the cavity through a pipe, takes heat away from the heating surfaces, and then is sent to heating devices (as an option, homemade registers made of smooth pipes).

Clarification. Instead of water, you can blow air through the heating plates - the stove will operate in heat gun mode.

A potbelly stove is suitable for heating 2 rooms of a small country house, workshop or change house. The duration of combustion in the heat maintenance mode is 2...3 hours, depending on the quality and type of fuel. Number of connected heating radiators – 2 pcs. heat output 0.8-1 kW each.

Drawing and operating diagram of a vertical round furnace

What to make a country heater from

In addition to a 50 liter propane tank, the following materials will be needed for assembly:

- sheet steel grade St20, thickness 4-5 mm - bottom of the water chamber;

- the same, 3 mm – doors, frames, heat exchanger fins;

- fittings Ø12…16 mm for the grate;

- cuttings of pipes with a diameter of 100 and 32 mm for the manufacture of connecting pipes;

- asbestos cord, fire-resistant basalt fiber.

To connect a water heating system, you can supply pipes Ø32…20 mm with ready-made threads. Before starting work, carefully disassemble the cylinder - remove the gas valve and pour water into the container.

Fins made from iron scraps play an important role - they increase the working surface of the heat exchanger

Assembly work procedure

The manufacture of a potbelly stove begins with opening the cylinder - here you will have to cut off the top part along the existing weld. Then we work according to the instructions:

- Make square holes in the side wall according to the drawing.

- Prepare the stove parts from metal - a round partition Ø30 cm, door frames 80 mm wide and the doors themselves. Attach the frames by welding to the body, as shown in the photo.

- Weld grate bars from the reinforcement, strictly adhering to the internal size of the vessel. Then the grid will fit tightly onto the welding joint without additional supports.

- Hermetically weld 2 threaded fittings to the cut off lid, where the water system lines will subsequently be connected.

- Place the round piece on the end of the cylinder, welding the seam on the side of the firebox. Attach heat exchange plates from scrap metal sheets on top.

- Place the cover with the fittings in its original place, mount the doors and weld the chimney pipe. For beauty, the stove can be painted with a black heat-resistant compound (sold in aerosol packaging).

Reminder. Do not forget to plug the top hole of the tank, where you previously unscrewed the valve.

Install the stove and chimney in accordance with fire safety regulations. Cover any combustible materials near the stove with galvanized sheets. Also maintain a distance of 0.5 m from the steel chimney to the wooden ceiling. If a sandwich pipe is used, the gap is reduced to 38 cm.

When installing water heating, take into account an important nuance: without forced circulation, the coolant in the heating chamber of the furnace will quickly boil. Connect the batteries in accordance with the diagram, install a dirt filter and a circulation pump on the return line. If you plan to heat the dacha periodically, fill the system with antifreeze.

Scheme for connecting the heating circuit of a potbelly stove to heating radiators

Advice. Select a pump for pumping water through 2 radiators with minimum performance, the volume of the expansion tank is up to 5 liters.

Bushcraft: Making a potbelly stove with your own hands

Potbelly stove . An ordinary metal stove, with a metal chimney. Once upon a time, or more precisely, in the first half of the twentieth century, such a stove was the only means for heating rooms. Of course, they were often used during wars. At the front or with the partisans, in field hospitals or command posts, in dugouts or dugouts, in train cars. And in cities, a potbelly stove was used when the central heating was turned off.

Today, the potbelly stove is widely used by owners of garages, greenhouses, garden houses and other premises not connected to central heating, with an area of up to 15 m2.

The content of the article

Advantages and disadvantages of a potbelly stove

Like any other heating device, a potbelly stove has its pros and cons.

Positive traits:

- Heating material is inexpensive. This is firewood, peat, wood chips, sawdust, and so on.

- To make a potbelly stove you need very little material, compared to, for example, a stone stove.

- The stove is compact and transportable.

- This heating device can be installed without a foundation, and a major chimney is also not required.

Flaws:

- Effective ventilation of the room is necessary, due to the fact that the potbelly stove is not able to accumulate the heat generated during combustion.

- The stove consumes fuel constantly and very quickly, so it is ineffective in constantly heating a room. Therefore, the oven should be used for heating or cooking only periodically.

However, the second drawback can be overcome by designing the product in this way: when creating a stove, you need to place the outlet pipe on the lid above the loading door. Thus, combustion products will enter the exhaust pipe and transfer heat to the walls of the chamber. Also, in order to improve heat transfer, you should line the potbelly stove with bricks. Then the heating speed will increase.

Types of potbelly stoves

The main material for making a potbelly stove is cast iron or stainless steel. In appearance, the stove is a bunker with a firebox door. You can also add an ash pan (with a separate door) and a chimney outlet.

Varieties:

- Oven with hob for cooking;

- Stove with hob, oven and burners;

- Heater furnace—having a casing around its body, the heater furnace is capable of effectively increasing heat transfer. Air is sucked into the space between the stove and its casing in the lower zone, rises, heats up against the walls of the stove and comes out in the upper zone from under the lid or through holes in it. The low temperature of the casing creates a surface that is safe for humans and will not burn you. The casing can be steel or ceramic.

- The gas generator furnace is a steel structure, coated with heat-resistant paint, consisting of two combustion chambers: the lower one is a gasification chamber; the top one is the afterburning chamber.

Instructions for making a potbelly stove from metal

A potbelly stove is made from an ordinary metal box the size of a regular barbecue grill. In addition, the material can be a forty-liter milk can, a steel keg for beer, an old gas water heater or a propane cylinder. But let's take a milk can as an example.

Manufacturing technology:

- A little below the neck in the can, you should use a chisel to punch a crescent-shaped slot for the blower.

- A hole is made in the bottom of the can for the pipe, onto which the chimney is subsequently installed. You can make the pipe yourself from a welding machine or buy a ready-made one.

- Next, a serpentine grate is made from 6 mm thick wire, which will be installed inside a homemade potbelly stove through the neck of the former can. You should experiment by stretching the grate to achieve the most efficient combustion of fuel.

- It is necessary to make support rings on the sides of the potbelly stove from half-inch pipes.

- You can attach legs to the bottom of the potbelly stove or simply install the stove on racks made of bricks no lower than 13 cm.

The longer the chimney pipe to the exhaust window, the less heat loss. Good tightness of the joints of the structure contributes to the complete removal of smoke from the outside of the room.

Instructions for making a potbelly stove for mining

Car owners do not need to be told what used oil is. But this type of waste can be used for good purposes, for example, as fuel for a potbelly stove during mining. This stove consists of two tanks, a connecting pipe and a chimney. The total metal thickness is 4 mm, and the thickness of the top tank cover is 6 mm.

The connecting pipe should have a diameter of 100 mm, the length should be 4 times greater than the diameter, approximately 35-40 cm. 50 pieces of 9 mm holes are drilled along the entire length of the pipe in the order: 8 pieces along the diameter, 6 pieces along the length of the pipe. A connecting pipe made of heat-resistant material is placed above the upper tank. The chimney must be 4 meters or higher in height.

Legs are welded to the bottom of the tank. A lid with holes for air and oil is tightly placed on its upper surface. Weld the lid with the hole + connecting pipe + upper tank.

How to use a potbelly stove

Used oil is poured into a cold oven through the filling neck; the amount can vary from 0.7 to 2 liters per hour. The main condition is that the fuel level should be a few centimeters below the tank lid. Then kindling material - newspaper, rags, etc. - is placed in the same neck. They are set on fire, observing safety precautions. Combustion is accompanied by a slight hum. Additionally, this version of the potbelly stove can be used to heat food and boil water. You cannot add oil to an oven that is already running. You need to wait until it cools down and only then refuel it.

Fire hazard of a potbelly stove

We have not mentioned one more drawback of the potbelly stove. This disadvantage is a great fire hazard. To eliminate the possibility of a fire, it is necessary to clear the space around the stove of easily flammable objects, including fuel.

It is strictly prohibited to use acetone, gasoline or other flammable substances in such ovens.

It is not recommended to allow water to get into the oil. To avoid the accumulation of carbon monoxide indoors, it is necessary to ensure good ventilation in the room.

Bushcraft

- (English

bushcraft

from

bush

- bush (wild desert area) and

craft

- skill) a set of survival skills in the wild. The term was originally used in Australia, New Zealand and South Africa in relation to survival in the bush, later spreading to other English-speaking countries and expanding its scope to survival in any wild environment.

Source