Author: Maxim Potashev

This type of bladed weapon has been legendary for thousands of years. Curved like the claw of a terrible beast, the blade worked wonders in the hands of eastern warriors. That's why so many people want to know the answer to the question of how to make karambit - an attribute of a real man.

Tiger Claw

“CS:GO” is a popular computer toy for boys of all ages, over 13-14 years old. Its plot is primitive, but the arsenal used by the heroes amazes the imagination with its vastness. From bladed weapons to firearms, everything is used to complete a rather controversial mission. Among the knives included in the KS-ki collection, as gamers briefly call the toy, the most notable knife is the karambit. It is shaped like a tiger's claw - just as curved and causing the same lacerations. On the handle of the knife there is a round hole for a finger - for a better grip, and also to show off such a weapon, turning it with all sorts of somersaults. You can buy almost real karambit by ordering it in one of the online stores. Or you might wonder how to make karambit from wood with your own hands and find a solution.

What it is

For those readers who are unfamiliar with edged weapons, it is probably worth explaining what we are talking about.

Karambit is a combat knife. Its shape may vary depending on the manufacturer and the anthropometry of the wearer.

All versions, however, have two characteristics:

- The knife has a sickle-shaped blade;

Please note: usually the blade is sharpened on the inside; You can rarely find double-sided sharpening.

- The handle is equipped with a hole for the thumb. It makes it impossible to lose the weapon in battle: even if the blade gets caught during a glancing blow, the handle will never slip out of the hand.

The evolution of weapons in different countries and even on different continents very often led to the fact that civilizations that had never contacted each other came to the same technical solutions. This observation fully applies to karambit: it was used in different cultures and, accordingly, has several names in different languages.

Here are some examples:

- Tiger Claw;

- Eagle Claw;

- Cock spur (chicken spur);

- Bladau;

- Kuku manan.

Let us clarify: the classic karambit has a blade length of 5-10 centimeters. The last two types of weapons are enlarged versions with blades of 20-30 cm.

Model assembly

Having cut out all the necessary parts from plywood using a jigsaw, they must be cleaned of dust and degreased. For gluing parts, synthetic glue for wooden surfaces or casein is suitable. It is necessary to use glue strictly according to the instructions so that the model does not fall apart over time. When the karambit has dried thoroughly, a hole for the thumb is drilled or sawed out on the handle. This stage of work should be as careful as possible so that the layout does not break. When everything is ready, the karambit must be sanded with sandpaper and again cleaned of sawdust dust. As you can see, the question of how to make a karambit knife from wood does not have a very complicated answer.

First example

The first drawing method, which will show us how to draw a karambit knife, will be more realistic. The next example will get more artistic. To draw, we will need a pencil, felt-tip pen or pen, this is not so important, because you can draw it with anything.

Let's start with the blade, it should look like a claw. Also, it should not be too long, since most of the length of this knife is occupied by the handle.

We depict the handle, we already said earlier, since the karambit has an unusual shape, the handle should be longer than the blade. Don't forget to draw a round hole at its end.

All the difficult stages are behind us and now the most enjoyable part remains - we detail our drawing. Let's draw a couple of lines on the blade.

Now let's draw the handle.

CS GO has a very limited selection of skins, but the artistic world is limitless. Therefore, you can choose absolutely any colors and patterns and paint the resulting picture.

Solid wood

There is another option on how to make karambit from wood. But it is available only to those who confidently work with wood, feel the wood, know the techniques and principles of working with tools for such creativity. The most suitable wood for handcrafts is linden. The block must be well dried, without cracks. The dimensions of the workpiece are taken slightly larger than the desired dimensions of the karambit. In order to correctly solve the problem of how to make karambit from wood, you need the following tools for handicrafts:

- knives with a fixed blade made of carbon steel with a hardness of 55-60 RC (blades must be different in size and configuration);

- chisels of different cutting edge shapes;

- vice;

- drills of different diameters.

For such work, you need not only a drawing diagram of a karambit, but spatial imagination, which helps in the correct construction of the stages of work.

Below is a photo of what a solid wood karambit will look like.

Artistic creativity

It’s not enough to know how to make a karambit from wood; you also need to paint it so that it looks like the real thing. There are several options for coloring (skins) of a knife in the game Counter-Strike: Global Offensive: from “Clear Water” to “Murder”. There are professional artists who, for a fee, manually paint models of karambits to look like real ones.

But you can try to paint your own karambit yourself. It is best to use acrylic paints - they mix well, are harmless, dry quickly and do not get dirty. The skin can be viewed on the CS:GO website, or you can come up with it yourself. The main thing is to turn on your imagination and desire to make a beautiful thing that looks like a real Tiger Claw knife. Good luck!

This type of bladed weapon has been legendary for thousands of years. Curved like the claw of a terrible beast, the blade worked wonders in the hands of eastern warriors. That's why so many people want to know the answer to the question of how to make karambit - an attribute of a real man.

Purposes of creation

The reader may have a reasonable question: is it reasonable in Russia, where carrying knives is illegal, to popularize their creation? Undoubtedly, military weapons should not be made at home. But a wooden knife with a short blade is safe enough so that the most vigilant law enforcement officer will not have any objections.

Why do you need a wooden blade?

There are two main motives for its creation:

- Practicing knife fighting and self-defense techniques without weapons is carried out using blades that most reliably imitate the shape of real ones, but are safer. A plywood karambit will not cause serious damage, even if dropped on it;

- In addition, for the last twenty-five years since the publication of J. R. R. Tolkien’s immortal trilogy in Russia, role-playing games based on fantasy and historical works have been very popular among our compatriots. Obviously, here, too, a reliable but safe imitation of a weapon will come in handy.

Information about edged weapons

Karambit is a specific knife that was created by one of the peoples of Indonesia. Among the distinctive features of the weapon:

- The blade is crescent shaped;

- The edge is sharpened on one side only;

- The presence of one or more rings for a more comfortable grip with your fingers.

The honor of discovering this instrument belongs to the population of one of the islands in Southeast Asia. According to legend, local residents, who deeply revered their king, believed that his soul had a tiger incarnation. And then they created a knife similar in outline to the claw of a bloodthirsty predator. Years passed and the Indians conquered the island. They perfected the technology and spread it to many other countries.

The variation of weapons that is in use in the modern world has little in common with the crafts of medieval artisans. There is a wide range of products on the market - from expensive, almost souvenir items, to extremely cheap products made from improvised raw materials. The device can also vary - even folding modifications.

Versions of origin

Today, karambit is used exclusively for offensive or defensive purposes. However, there is no consensus in the scientific community regarding the origin and original purpose.

Among the most popular hypotheses:

- Agricultural implement

. At first glance, the object has an unambiguous resemblance to a sickle. The widespread use of their manufacturing technology could prompt blacksmiths to improve them in a completely different direction. - Melee weapons

. Some researchers speculate that this knife was originally brought from the Hindustan Peninsula at the beginning of the second millennium to the territory of modern Indonesia. There it was slightly modified by local residents. For example, there is a legend about the use of poisonous blades in battle. - Perhaps this was an element of spurs

during competitions involving fighting cocks. This version is considered by some experts to be the most plausible. During fights, one bird inflicted such wounds on another that people could not help but think about using this terrible weapon for their own purposes.

In this video, edged weapons expert Eduard Morozov will tell you why people buy karambit and how to use this knife:

How much does karambit cost?

Modern karambits are extremely high-tech products. They are manufactured from the best raw materials and using advanced technology. The world's leading arms companies sell these products all over the world.

Among the most famous brands of this type of knives:

- "Elemental Knives";

- "Warren Thomas"

- "Mantis Knives";

- "Emerson Knives";

- "Spiderco";

- "Craig Camerer";

- United Cutlery;

- "Mike Snody";

- Cutters Knive & Tool.

For their high-quality product, these manufacturers ask a lot of money for the average Russian - about 150 US dollars, which is almost 10,000 rubles at the current exchange rate. Obviously, few people can decide to give three-quarters of their salary for a chic, but still trinket.

Therefore, you can turn to numerous Chinese stores or free classifieds sites. Of course, the quality of crafts from unknown brands is not amazing, but you can buy “the same” karambit for a ridiculous 1,000, 800 or even 300 rubles.

How to make a karambit knife?

Anyone who is not looking for easy ways can try to make a legendary knife themselves. To do this you need to adhere to the following technology:

- First of all, you need to find steel. It is desirable that it be good quality material. You can find something as a raw material at the nearest construction site or landfill. As a rule, chains, wire or cables will do the job for an amateur knife. In any case, each master has his own favorite material. Therefore, it is worth practicing a little before you risk forging your own knife.

- In order to determine whether the found material will be suitable for forging, you need to conduct a series of experiments with it. First you need to turn on the abrasive wheel for sharpening knives and bring the metal to it. If the flow of hot dust turned out to be quite dense and, moreover, had a fiery hue, then everything is in order.

- Then you need to modify the metal at high temperatures. After it softens a little, you need to cool it.

- The next step is to create a blank. The raw materials are properly pressed and the reinforcement holder is welded.

- After heating in the oven to 850 degrees, you need to add reagents that protect the metal from severe oxidation. Only now can welding be done.

- As soon as the previous stage is completed, you can proceed directly to forging. During the procedure, you need to ensure that the crescent shape is maintained.

- Then heat treatment and hardening are carried out, after which the blade is lowered into a vat of oil for cooling.

Second drawing method

Let's look at a more artistic drawing that will show us how to draw a karambit step by step in just three steps. It is almost the same as the previous one, but the style itself is slightly different.

So, we depict a blade that looks like a dinosaur claw or a bird’s beak; everyone sees something different in it.

We draw a handle and separate its tip for the future ring. If you look at the picture below, you will see that the karambit has a very unusual shape and is a bit like a boomerang.

The final step will be detailing our bladed weapons. We make the ring voluminous, and shade the rubber inserts with diagonal lines.

The drawing is ready! All you have to do is choose your favorite colors and paint it.

In this instruction we will look at how easy it is to make a knife like a karambit. A special feature of these knives is the curved shape of the blade. There are many versions of what these knives were intended for and where they originated. In most cases, these knives are associated with the tiger claw, and its purpose is self-defense. Such a knife lies comfortably in the hand and will instantly make the attacker change his outlook on life.

There is also a version that these knives resemble a cock’s spur, and according to another legend, similar knives were used for cockfighting. There are also versions that such a knife can be used for some craft purposes, for example, cutting some plants. One way or another, let's hope that you will use such a weapon for good.

Making such a knife is not difficult, and you can get by with fairly simple tools. The product is all-metal, so you will not need any additional materials. The author cut out the profile with a grinder.

If you need such a knife on the farm, then it makes sense to make it from high-quality steel. Steel with a high carbon content can be hardened. When cutting, carbon steel produces thick yellow sparks and is found in cutting blades, files and other tools. So, let's take a closer look at how to make such a knife!

Materials and tools used by the author:

List of materials:

- carbon steel.

List of tools:

- Bulgarian; — belt grinder; - drilling machine; - drill; - various files; - sandpaper; — forge furnace; - polishing machine.

The process of making a karambit knife:

Step one. Making a template

First of all, we need to make a knife template.

To do this, we make some drawings on a computer or manually. Next, print out the resulting drawing and cut it out with a utility knife. That's all, the template is ready, trace it on the workpiece with a marker and you can start cutting. Before drawing the drawing, the author cleaned the metal on a belt grinder. Step two.

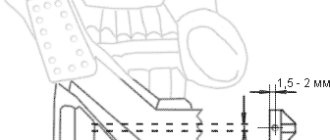

Hole First, let's drill a hole in the workpiece using a bit.

This strategic hole is for fingers. To securely hold the blade, most karambit style knives have it. Drill the hole slowly and lubricate the bit well. We always securely fix the workpiece and under no circumstances hold it with our hands, since if the metal breaks out, it will cause serious injuries to our hands. Step three.

Cutting out the main rough profile Let's start cutting out the main profile.

For these purposes, the author used an ordinary grinder. To cut out the curves, we make a lot of cross cuts, and then cut them out in parts. As a result, teeth will remain, which can also be removed with a grinder by installing a sanding disc. Step four.

Grinding We go to a belt sander and carefully grind the blade along the contour. It is important for us to remove all the notches and sharpen the blade in the shape it was originally intended to be. In most cases, the author uses 400 grit tape. Next we have to do some manual processing. We clamp the workpiece in a vice and work with files of different shapes. We process the blade along the contour where we could not get close with the tape machine, and also grind the hole.

Step five. Cutting out windows in a pen

The author decided to cut out windows in the handle, so the knife looks more interesting.

To solve this problem, take a drill and drill a series of holes of the desired shape. As a result, we then combine all the resulting holes using a file or the same drill. We thoroughly process the resulting windows with files. Step six.

Forming the bevels It's time to form the bevels on the knife.

To do this, we clamp the blade into a special bracket made of corners, since it will be difficult to hold it with your hands due to heating. The author forms the bevels by eye using a belt sander. But first it would be good to mark everything out. The grain size of the tape for such work can be around 400 units. You must complete all the basic metal work at this step, as the next step is hardening, and the metal will become strong. Step seven.

Hardening It's time to harden the blade, this will make it very strong. For proper hardening, it is important to know the grade of steel. We send the blade to the forge, it needs to be heated until the metal is no longer attracted by the magnet, but these are only approximate figures. Well, then cool the blade in oil. Now the blade should be hardened, but after this the metal will become brittle, the blade may crumble simply when dropped. We need to make the blade more elastic so that it springs back under load. To do this, metal is tempered. Usually a household oven is used; we select the time and temperature depending on the grade of steel. On average, the blade is heated for about an hour at a temperature of around 200 degrees Celsius. The straw color of the metal will indicate the release. That's all, now we have a blade of excellent quality.

Step eight. Final processing

Now, after hardening, the metal needs to be sanded again, or you can leave it as is, this patina will act as protection against rust. We grind the surfaces on a belt sander and use it to sharpen the blade. As for the holes, they can be processed using a drill. As an option, the author screwed a piece of sandpaper onto the rod and clamped it in the drill chuck; this attachment also works great.

That's all, all you have to do to finish is polish your creation on a polishing machine. That's all, the project is over,

This type of bladed weapon has been legendary for thousands of years. Curved like the claw of a terrible beast, the blade worked wonders in the hands of eastern warriors. That's why so many people want to know the answer to the question of how to make karambit - an attribute of a real man.

Karambit made of plywood

In martial arts classes there are many elements using karambit. However, using this formidable weapon for training purposes would be extremely dangerous. Therefore, for beginners, knife blanks are made from relatively harmless materials: paper, cardboard, plywood, etc.

Here is the procedure for making the blank yourself:

- Ready-made knives for training purposes are sold in specialized stores or on websites. The most common ones are plastic ones, which are relatively inexpensive.

- There are ready-made construction kits on sale, from which you can make a high-quality copy of a real karambit in a matter of minutes.

- You can print a karambit knife on a 3D printer. On the Internet you can find many ready-made circuits for these printing machines.

- If you decide to make a knife from plywood with your own hands, then you must first thoroughly study the information on the World Wide Web and find a suitable drawing.

- Then you need to print out the selected diagram and use it as a stencil: apply it to a piece of plywood and then carefully cut out the resulting shapes.

- After this, all components must be glued together (usually the entire sequence of connecting parts should be attached to the drawing).

- The last stage is finishing: removing bumps, painting, etc.

Advantages and disadvantages

The strengths of this product include:

- Serious power to defeat in close combat;

- Effective transfer of energy to the human body;

- Good feedback;

- Almost impossible to take out of your hand.

Among the shortcomings, the most significant:

- Karambit is primarily a weapon, and it cannot cut bread. This must be kept in mind if it is given as a gift.

- At the beginning of the battle it is quite difficult to start using it due to its unusual shape;

- Limited number of possible attacks and techniques for striking.

For a person who has golden hands, there are many ways to make karambit. You can forge a weapon from metal. You can find drawings and make a craft from plywood. No one even bothers you to print a knife on a 3D printer. If, of course, you have one.

Manufacturing

So, how can you make a fairly reliable imitation with your own hands?

Sawing blanks

Dear reader, do you have a jigsaw? Yes? Great, put it aside and forget about it.

There are two ways to cut a wooden blank of complex shape from plywood with a thickness of 4 - 12 mm:

- Hand jigsaw;

- An improvised cutter, which can be a stationary circular saw or an angle grinder with a saw blade installed. In the latter case, the workpiece is securely fixed with a clamp.

Attention: if you are going to work with a grinder converted into a saw, do not forget about safety glasses and be extremely careful. In particular, you can put the tool on the table only after the disk has completely stopped.

The holes in the handle are selected with a ballerina or a feather drill of the appropriate diameter.

Gluing

Universal PVA glue is quite suitable for it. The price of a small tube that we will need will be no more than 20-30 rubles.

The pieces will have to be glued and dried under pressure:

Grinding

It can be done:

- On a belt or disc sander;

- On sandpaper;

Attention: emery grinds down soft wood very quickly. The workpiece is pressed against it with minimal pressure.

Knives in CS:GO

are one of the most expensive and very rare items, so absolutely all players dream of having at least one copy in their inventory. Some users are so fanatical about knives that it gives them the motivation to design homemade karambits, hunting knives, butterfly knives, and so on.