An electronic laser level is one of the most necessary tools needed by both builders and people of other professions. While using this level, you can project the intersecting points and see if you get a right angle. Buying such a device in a store can reach up to 100-200 dollars, and if you spend a little time and effort, creating a homemade laser level will cost pennies.

The cost of a laser level is quite high, and if you plan to use it only a few times, then such a purchase will be inappropriate. Therefore, you can do it yourself.

This tool will come in handy during construction work.

:

- During installation of floor and wall tiles of different sizes;

- When pouring the floor with concrete or other material that requires uniform distribution;

- When pasting wallpaper, both on the walls and on the ceiling;

- During the installation of suspended ceilings and windows.

Making a construction laser level with your own hands is not difficult. A

In terms of its qualities, it is not inferior to the purchased one; you only need to prepare some materials.

Namely

:

- Cheap laser pointer, sold in any children's stores;

- A small piece of porous rubber, preferably thick enough;

- Regular bubble level of small size;

- A sanded block of wood the size of a matchbox;

- A small, flat stick that serves as a support;

- A bar corresponding to the length of the level;

- A small piece of plywood sheet measuring 10 by 10;

- A clamp corresponding to the diameter of the pointer - it is necessary to secure it;

- The required number of screws.

After preparing all the materials, you can start working.

Differences between a homemade model

A homemade laser level can be used for mirror and symmetrical markings over long distances during construction or repair. Of course, the homemade version has a short range of action: approximately 10-12 meters. But this is quite enough to complete most of the necessary notes. Professional devices are capable of creating marks, calculating angles and much more. But the big disadvantage of such devices is their price.

Some of the electronic models start at two hundred dollars, which is not that cheap. But in most cases, many of the proposed capabilities of professional equipment will not be needed, so you can get by with a homemade design. A homemade level will cost tens of times less, and you will need available materials to assemble it.

Tripod or adjustable support option

You can place your DIY laser level on a tripod or adjustable stand. It will be quite a convenient and functional design. Tools you will need:

- drill;

- set of wrenches;

- hammer;

- needle.

The materials we use are:

- wooden block;

- laser pointer;

- bubble level;

- electrical tape;

- plastic clamps;

- scotch;

- nails, screws, self-tapping screws or screws;

- plastic and wooden planes of the same size (planks, tiles).

The design idea is quite simple - the laser pointer is placed on a movable element. Using such a device, you can make markings 360 degrees around an axis at the same level. We will need a children's or more powerful laser pointer, depending on the budget. It is with this small element that the work begins. How to make such a device is described below:

- Let's start with modifying the pointer. The glass or plastic lens must be removed from the attachment. Instead, you can place a small piece of cardboard inside or cover the hole with electrical tape on the outside.

- Next, using a needle, you need to make a hole exactly in the center where the beam will pass. The small hole made by the needle will reduce scattering and increase the accuracy of the instrument.

- The next element is the platform. To make a movable plane, you can connect a plastic plate and a wooden plank of the same size with a self-tapping screw. This part will allow our device to rotate around its axis.

- We place a bubble level on the platform, and on it a rubber shock absorber (a piece of rubber of a suitable size).

- We install a laser pointer on the rubber and secure it with tape, clamps or other possible means.

The homemade design is ready. But it must be tested before work.

For calibration, you can select two points, mark them using the resulting laser level and connect them with thread or fishing line. Check the slope with a level. If there are no mistakes, then the equipment is suitable for creating marks.

Step-by-step description of the work on manufacturing an optical level

Stage 1. To make two small dovetail-shaped fastening blanks, we take an aluminum sheet. They will be used as a support stand for the purchased optical sight and the elements connecting it and the level. It is necessary to correlate the dimensions of the workpieces, the dimensions of the sight legs, and the distance between them.

Stage 2. We take aluminum plates, use a hacksaw to make deep cuts to accurately make a groove - and insert the sight into it. To make a groove, we use a tetrahedral file - it should have strictly perpendicular edges. The slot will serve to securely fix the sight. When choosing the width of the groove, you need to focus on the dimensions of the scope body.

Stage 3. You need to take the plates and spirit level, and make holes for the bolts. We attach aluminum blanks to the surface of the level. The sight can be attached in any other way - the main thing is that it must be clearly fixed and not change its position relative to the building level.

More mobile option

The disadvantage of the first type of structure is its limited mobility - only horizontal rotation. If there is a need to make marks not only horizontally, but also vertically, you can try to build the following type of structure:

- You will need a plastic or wooden base.

- A small pin, bolt or screw is secured to the base. The last elements are placed with the cap down.

- A wide articulated fork clings to the resulting mount.

- The articulated fork will house a plastic or wooden narrow piece on which the laser pointer will be attached.

- A hole is drilled in the workpiece with a diameter equal to the screw, which will pass through it approximately equal to the diameter of the fork ears.

- A pointer is attached to the workpiece, and if there is space left, a bubble level is used.

Thanks to this type of design, the vertical angle of the position can be changed. Depending on ingenuity and the fork found, almost a full 270 degree vertical rotation can be achieved. Using a nut with lugs, you can quickly unscrew the fixation screw and change its position. It is worth considering that the larger the fork, the wider the base will be needed to ensure a stable position. The design can also be improved:

- You can make a groove in a wooden blank in which to conveniently and securely attach the pointer.

- In the adjusting screw, you can use either a regular nut or an element with ears, but the second is much more convenient.

- The design with a pin without thread will be collapsible. To make it stable, you will have to select the appropriate diameter of the connecting element of the hinge fork. In the case of threads, you can also use homemade forks.

- If you don’t have a fork, its semblance can be made from a metal-plastic ring of sufficient strength, you just have to choose the right diameter. You will need to make three holes: two on the sides, opposite each other, and the third at an equal distance from the two future “ears”. Next you need to cut the ring opposite the last hole. You will get a semicircular blank with a hole at the bottom and ears for the bolt on the sides.

- To prevent the homemade fork from loosening and twisting too much when turning, you can place a rubber gasket under it.

Advantages of using a laser level

A homemade light indicator allows you to apply mirror-like, symmetrical markings and mark spatial points at a large distance. The range of action of such models does not exceed 10 meters, but this distance is sufficient to perform most of the necessary marking work. Professional devices (construction level, cut indicator) have greater functionality, but many of the available capabilities are not always in demand. Therefore, at home you can get by with a homemade design.

The characteristics of such a level are quite sufficient to satisfy the basic requirements and apply the necessary markings, because it:

- provides the required beam range, up to 10 m;

- increases measurement speed;

- guarantees an acceptable minimum error.

The main advantage of the device is the positioning of the light beam in the horizontal plane, which allows you to effectively mark structures and control levels, including vertical ones on the wall. In addition to carrying out repair work in an apartment, house and interior design, it is used to lay out the plot of the personal territory, control the construction of fences, and decorate the facade.

Leveling from a laser pointer and bubble level

One of the available options for making such a tool at home is to upgrade a conventional bubble level. The idea is to attach a light pointer to the body of the level, which will expand the possibilities of using the instrument and allow you to place points on distant planes. If you additionally adapt a tripod with a rotating platform, the efficiency of its use will increase noticeably.

During production you will need:

- bubble level, medium size;

- laser pointer;

- rubber, hard foam rubber, polystyrene foam with dimensions 40/15/5 (length/width/height in mm);

- for fastening, worm clamps, nylon ties in the amount of 2–3 units.

The level should be taken with handles in the middle of the side edge, through which it is more convenient to attach the laser pointer with clamps or ties. The requirements for the indicator are simple - the light point at any distance must remain clear and not blur. To do this, rotate the cap on the laser side, under which the focusing lens is hidden. Depending on the direction of rotation, the outline of the point will change. The adjustment is carried out in such a way that deviations from the original shape of the light spot are minimal, regardless of the distance.

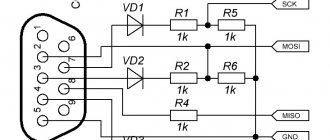

1 – laser pointer; 2 – rubber backing; 3– clamps, ties.

The device is attached to the top, where the insert with the bubble is located. First, lay the substrate, a prepared piece of rubber, foam rubber, or polystyrene foam. Then there is a light indicator, which is tightly secured with nylon ties and worm clamps.

The direction of the beam is set strictly parallel to the edge of the level. The adjustment is made by placing the instrument on any long, flat surface, this could be the top of a table installed against the wall. The height of the light beam from the base should be the same throughout.

If there are no holes suitable for attaching the handle, then in order to securely fasten the light indicator, drill them yourself in the most suitable place with a 3 mm drill. Further fastening steps are similar to those listed above.

To carry out marking in different planes, the tool is applied to a base that is set strictly horizontally or vertically. By rotating it around its axis, the marks are transferred to the walls, ceiling, and floor. Instead of a surface, it is allowed to use a tripod with a rotating element with a fixed flat board or metal plate.

Step-by-step instructions for making a laser level

Stage 1. We take the laser module, wind the wire with a spring, leave two tails of the required length on the left and right to ensure more reliable subsequent fixation of the emitter.

Stage 2. We place the laser module on a foam base and fix it on both sides with four nails - 2 on each side.

Stage 3. Take a transparent bowl, pour water, and place a foam platform with an emitter on the surface of the water. As a result, no matter how smooth the surface on which the bowl is located, the water will always act as an exact level, perfectly leveling its horizon. For this natural level, it is enough to have a running water system and a bottle of water nearby.

Setting up a homemade pointer

Before starting important marking work, any device made independently, for example, a do-it-yourself laser level, must be calibrated and configured. You can do this yourself as follows:

- A self-tapping screw up to 120 mm long is screwed into the base on which the level is fixed. Deepening it so much that its cap coincides with the line of the laser pointer.

- Having turned on the pointer, the beam is directed at the wall, after which the projection location is marked with a pencil and a second screw is screwed into it.

- A profile or a flat piece of drywall or any strip is installed on the screw heads.

- Laser on top. If necessary, the bar is aligned with the horizon, taking into account the readings of the bubble, tilting the edge located closer to the wall.

- After alignment, a new screw is screwed in and the profile is removed.

- Having installed the homemade device on the stand, make its final adjustment, focusing on the head of the last installed hardware.

- If the device is level, proceed to marking.

The main advantages of a homemade tool

It is important to understand when using a home-made device that it is impossible to obtain ultra-precise data from it. Operations performed by the device can be in open space, short distances, unlike purchased analogues. At home, a modified laser level will allow you to use the mechanism instead of a conventional bubble device.

Main differences:

- The marking speed increases significantly, because the level sets exact values on the plane. When working with a partner, it is possible to mark a room in a matter of minutes, which significantly saves valuable time.

- An error exists, but its value is minimal and is suitable for almost all types of finishing work. The simple design allows even a novice master to use the device.

- The length of the beam depends on the power of the purchased laser; for large volumes it is possible to increase the parameter using special material purchased from radio components.

The main advantage of the device is the possibility of projection on a horizontal plane. This feature allows the home craftsman to control the quality of marking in both vertical and horizontal positions. The laser structure is used for finishing work, furniture installation, and other types of construction. It is also possible to use a self-made level outdoors when constructing fences or small extensions.

Every home craftsman understands the importance of the device, but there is no need to go straight to a hardware store. You need to understand exactly that if the work is not so complicated, you can make the mechanism yourself from improvised means, significantly saving your budget.

After making a homemade device, you need to configure it correctly. When using the option with a water measuring system, there are no problems; the main adjustment requires the supporting structure.

The process goes like this:

- The peg is installed into the floor by driving it in or using a mounting stand. The support is screwed in until it coincides with the bubble level in the ideal position.

- The indicator turns on and is aimed at the required surface. By carefully rotating it is possible to mark the walls.

- A self-tapping screw is screwed in in the marked area, a second place is marked nearby, after which the rail is installed.

After adjustment, the level is moved a short distance to check, if the values match, it is possible to continue working. When working with the tool, you must take precautions, wear safety glasses, and avoid direct contact with the beam in your eyes.

When using a homemade structure, it is important to monitor the exact markings; if the device goes wrong, you can get incorrect readings. It is necessary to monitor the vertical or horizontal position of the beam, and when using a foam component, wait until the device takes the desired position.

When carrying out repair and construction work indoors, it is very convenient to use a laser level to draw a straight horizontal or vertical line. But it doesn’t make sense to buy this device just for 1-2 uses. Very expensive.

However, there is an alternative option - you can make a laser level with your own hands. It will be much cheaper, and it will cope with constructing axes on a plane no worse than a conventional linear laser level. There may be an error, of course, but not critical.

To make this homemade product you will need a Chinese laser flashlight, a piece of profile pipe, an aluminum or steel tube, a small piece of mirror and a 12V electric motor. That's the whole set of materials.

Application of the gimbal

Any suspended massive object will rotate freely around an axis pointing straight down. If the pointer is fixed perpendicularly, its beam will draw a horizontal line on all boundary walls.

Take a wooden block, into the upper end of which two screws are screwed into the edges. Their caps should protrude by about 1 cm. Any thick thread, preferably one that stretches slightly, or thin copper wire is tied to them. Another piece is tied in the middle of the thread, with which the workpiece will be suspended on a tripod or hook.

Using rubber bands, worm clamps attach the laser pointer to the bottom of the block, ensuring its perpendicular position. The direction is checked with a regular bubble level. By changing the length of the suspension thread, the beam is set relative to the first mark on the wall. By turning the beam with the pointer attached to it, further marking of the longitudinal line is carried out.

To view its location in the plane, the beam with the suspension thread is slightly twisted in one direction. When released, it will begin to spin in the opposite direction under the influence of gravity, and the pointer will draw a strictly horizontal line along the walls. The error is no more than 1–2 mm.

Using a water container

You can make a simple design with a high degree of marking accuracy from materials available at home. To do this, you will need to prepare a water tank, a piece of foam plastic (expanded polystyrene), a pointer, any sticky material - plasticine, adhesive tape.

- First, the container, which can be used as a bucket or pan, is filled to the brim with water.

- The laser pointer is installed on foam plastic, trying to place it evenly, and secured with plasticine, adhesive tape, and rubber bands.

- The container is installed at the required height.

- Styrofoam with a pointer is placed in the tank.

- Move it to the on position.

- By changing the direction of the light pointer and rotating it around its axis, the beam is projected onto the marked surfaces and the projection locations are marked. All points relative to the horizon will be strictly in the same plane.

Homemade laser devices can hardly be called ideal, but the clarity of the markings applied is very high. Another advantage is that anyone can assemble such a tool with their own hands from available materials, spending a little money and time on its production.

If you are starting a home renovation project, then you will definitely need all kinds of tools. Such devices can be easily purchased in hardware stores and on the Internet. The only problem may be the high price. Fortunately, many tools can be made by yourself.

Laser level

One of the most expensive types of instruments. This device is used for professional work or more complex repairs to determine how smooth the surface is.

This level will easily indicate both horizontal and vertical marking lines for you. There are also devices that have a cross beam. A special advantage of this tool is that it is installed either on a stand or on a plane and, using a special air indicator, is leveled horizontally or vertically to the nearest millimeter.

Types of devices

Since the production of tools does not stand still, the variety of leveling levels is constantly increasing. Now you can find several main types that are most often used in repairs.

- Floor

- Wall

- On a stand

The names of these species speak for themselves. The floor is installed on a flat horizontal surface. It is important to know: if the level will be installed on a table or other surface, it must be centered.

The wall level is installed on a vertical surface. There are special mounts on it to keep the device on the wall. This level is useful when marking vertical guides and other materials during repairs. For example, if you are hanging paintings in an apartment, then this type will provide you with maximum symmetry between the paintings.

The laser level on the stand has a special sight and beam. Usually the beam has a cross glow, which immediately determines both the vertical and horizontal lines. This level will facilitate any type of construction, especially finishing work. It has a special water device that shows how level you have set the rack. Before work, it is important to set up the tool correctly, because the evenness of all your material depends on it.

In other types of level, an electronic computer is installed on a stand instead of a water device. It is much easier to use because if set up incorrectly it will self-level.

DIY laser level: proper use

It’s not enough to make a laser level at home, you also need to know how to use it. You need to fix the stick with the sharp end down on the desired surface, then using a bubble level, level the angle of the bar to achieve the most accurate horizontal position. You need to turn on the laser pointer and carefully point it at the desired surface.

After the pointer appears, you need to make a small mark, then move the pointer a little to the side to accurately check whether the level mark has gone astray.

Once there are two points, you need to draw a horizontal line connecting them. If the result is a perfectly straight line, the level is working and installed correctly. The dots indicate whether the stand and stand are installed perfectly. When working with such a device, it is better to have safety glasses to relieve eye strain. Adjustment will be even faster if you use a plumb bob to help with the work. A homemade laser level has a bit of a primitive design, but the ability to save a decent amount of money mitigates this problem.

Experts highlight a number of advantages that a home level has

:

- The beam length is sufficiently long, allowing it to be used in almost all work related to repair and construction;

- A small level of error, which is an insignificant drawback;

- High speed of marking and convenience, which a regular bubble level does not have;

- But builders highlight the main and most significant feature - the ability to project rays in a horizontal plane.

The homemade device can be used in further work; it will serve faithfully during the construction of a fence, if necessary, mark the boundaries on a personal plot, during the cladding of any structure. Professional workers will need purchased levels, they come in these types. Bubble - it is a plastic or wooden case with three flasks inside. Each of them is filled with alcohol and has a bubble, it should be located in the middle, indicating the exact location.

Water - they are a hose of small diameter and up to 25 meters long, with two flasks, all elements are connected to each other. Each flask has a printed scale; such a device has both advantages, in the form of low cost, and disadvantages - you need to be careful when pouring liquid, and it only works on horizontal surfaces. Magnetic - their advantage is ease of mounting - it is quickly and firmly installed on any metal surface and gives accurate readings. Tubular - it is made in the form of a rectangle and is equipped with a magnet and a cord. Laser - it is characterized by high accuracy and range, but has one significant drawback - high cost.

Manufacturing technology

You can make such a level with your own hands from a laser pointer. It is enough to know the structure of a laser pointer and the structure of a conventional construction tool.

If you take into account the price of a water level and a regular pointer with a beam, it will be several times cheaper than a professional tool.

Step-by-step instruction

For a laser pointer you will need:

- Water level

- Laser pointer

- Fastenings

When choosing a water tool, you need to pay attention that the back side is smooth, otherwise the pointer will be inconvenient to attach. The laser pointer should also have a flat surface.

They are connected using glue or tape. It is important to set the pointer as level as possible to the water level. After the joints have been glued, you need to use a ruler to measure the distance from the bottom of the water level to the very sight of the laser pointer. The resulting size will indicate the bottom of the mark from the direction of the laser beam.

Making a laser level with your own hands is not so easy. It will require not only the above materials, but also a device for installation. For example, it could be a stand made of wood or metal. It will not be possible to assemble such a tool from available materials. You need to correctly calculate the holder for the level.

The instructions for assembling such a level indicate the accuracy of its geography when used. If you go to hardware stores, you can find a round water level that ensures the evenness of both surfaces at once. If you assemble and install it on your pointer, you can easily use this device for home use.

Remember that a professional tool is built much better than a homemade one. And when creating and using homemade devices, you are more susceptible to construction errors. After all, if it is not possible to buy an expensive instrument, you can always borrow it from friends, neighbors, or rent it from special companies.

In construction and finishing, precision is important, which can be perfectly maintained using a laser level. This is an expensive tool, so purchasing it for a one-time repair is impractical. For small jobs, you can make a level yourself from a point laser pointer. It costs less than $3, which makes homemade a budget alternative to a specialized tool.

Laser cross

This is another version of a homemade laser level - using a laser cross. It is very convenient if, for example, you need to hang a picture or shelf, when working with drywall, etc.

In order to make a level with a laser cross ourselves, we may need a stand from an old video camera (tripod), on which the entire structure will be installed, a broken CD player and a couple of CDs.

The laser cross must be mounted on a tripod so that it can be rotated around. To do this, you need to fix the CD drive on the tripod, which we will remove from the player. The fastening mechanism must be designed so that the position of this drive in space can be adjusted (higher or lower). Next, take one or two CDs glued together and install them on the drive. After this, you can attach a laser cross to the disks using, for example, tape or plasticine and our level will be ready. Thanks to the drive from the CD player, by installing the tripod correctly once, we will be able to rotate the laser cross in the direction in which we need it. This eliminates the need to re-attach the laser cross each time you rotate or move the tripod.

In order to make a more or less normal laser level, you need to tinker a little. Of course, there are many ways, including fixing a laser pointer to a water level, and many others.

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you;)

Materials for assembling a laser level

To make a homemade level you will need:

- wooden block 30x30 –20 cm;

- tube (according to the outer diameter and length of the pointer);

- a motor from a children's toy;

- crown battery;

- crown terminal with wiring;

- key mini switch;

- a miniature mirror for cosmetic powder or lipstick;

- ballpoint pen paste;

- laser pointer.

For assembly you will use a hacksaw, a glue gun and a soldering iron. Ideally, in the future, use an adjustable tripod to install and adjust the level.

A full-fledged level from the remains of a laser printer and a pointer

For those who are not looking for easy ways, you will need:

- laser unit from a non-working printer;

- laser pointer;

- a motor from any children's toy or from a broken CD drive;

- rubber belt;

- button and 9 V battery (crown);

- slotted and Phillips screwdrivers;

- soldering iron with solder.

Remove the laser unit cover. Under it you will find a hexagon or square mounted on a stepper drive, a curved lens and a mirror, as well as a native laser. However, the latter produces an invisible color, so it can be replaced with a laser pointer. The laser beam, hitting the side faces of the hexagon at an angle, is reflected into the lens, and then through the mirror into the exit slit. The hexagon constantly rotates and the laser point very quickly draws a line, the flickering of which is not even noticeable.

It is very difficult to control the drive driver for the mirror hexagon. It is much easier to attach a third-party drive and connect its shaft to the hexagon using a belt.

Measure the distance from the axis of the hexagon at which you can install the motor so that the belt is slightly tensioned. The result is a sector running around the body in a circle. Choose a place where the motor will not interfere with the laser beam and can be easily secured with glue. If necessary, drill a hole and install the motor, connect its shaft to the hexagon axis.

Remove the original heatsink with the laser and its driver board. Attach the laser ruler so that it shines in the same direction.

All that remains is to power the motor. Connect the motor, button and battery in series. If desired, a laser pointer can also be connected to the same battery, in parallel with the motor.

On the sides of the exit slot, two screws or pins made of 2.5 mm or more wire are fixed on the body of the laser unit. A thread is tied to them, and then the laser level can be used, as in the previous version.

The video shows a version of a homemade level using a mirror

A bubble level is used to set the line in the horizontal plane. It is quite possible that you will have to adjust the focus of the pointer, so it is better to immediately remove the top decorative cap and use pliers to correct the shape of the beam so that you get a thin line at the exit of the entire structure.

A laser level is an indispensable thing for a builder, because in his work every now and then it is necessary to make markings on walls, floors, and ceilings for attaching various types of interior elements; a laser level may also be needed at the beginning of a new construction, for example, to mark the area for a foundation . This is quite expensive equipment that only professional builders can afford to purchase. Everyone else, if it is necessary to carry out work that requires the use of a level, has to make do with the old old-fashioned methods. In order to somehow facilitate the work that requires the use of a level, in this article we will look at one of the many options on how to make a laser level with your own hands, a little primitive, but still...

Assembling a level from a pointer

First you need to make the base for the level. A 30x30 mm block is suitable for this. It is enough to cut 20 cm. A tube of thick cardboard (or plastic) is glued to it with a glue gun. It is selected in such a way that the pointer fits tightly into it. The length of the tube is approximately 15 cm. A motor from a children's car is glued to the end of the bar farthest from the end of the tube. Its shaft is aligned with the focusing line of the pipe cavity. You need to assemble the motor power supply system. To do this, a mini switch is soldered to the wiring of the terminal installed on the crown. The battery and it are glued to the block. All that remains is to select the appropriate length of wires to solder it from the switch to the motor. A direct wire from the terminal is soldered to the second contact of the motor. Now you need to take a small mirror. It’s not difficult to find this - just peel it off in any unnecessary women’s cosmetic bag. The smaller and lighter it is, the better. You should find the center on it and draw a transverse line. An adhesive layer is applied over it and a ballpoint pen paste or Chupa Chups stick is glued in. The glued tube is placed on the motor shaft. If the mirror is balanced correctly, then when the engine is turned on, the design with a homemade blade almost does not vibrate. The level is ready, all that remains is to fix it on the tripod. This is done in different ways, depending on the design of the stand. In my case, you need to press the nut into the block and screw the tripod platform onto it.

How to use

A pointer is inserted into the level tube.

Since it enters with force, its button is pressed and the LED lights up without ceasing. Now, if you turn on the motor, the mirror rotating on its shaft will reflect the laser beam. Buying an expensive level for home needs does not make sense, since this device costs a lot of money, and it does not need to be used often. If you need to draw an even horizontal line on the wall, or install the structure parallel to the ground, you can make a laser level with your own hands, using available materials that can be found in any private home. This will not take a lot of your time and money, but you will get a good tool that you will use for many years. Next, we will provide two simple master classes on making a homemade level by hand; the work will take you no more than half an hour.

How to make a simple level?

Usually this question is asked by home craftsmen: when starting any construction on a suburban site or household repair work in a residential building, one cannot do without breaking down the axes.

To carry out the correct geodetic marking of the area and calculation of the elevation of the earth's surface or to mark vertical and horizontal guides for the ideal installation of a cornice, washing machine or bookshelf, gluing the first strip of wallpaper and many other household tasks, a fairly easy-to-use device - a level - is called upon. Based on the type of design, levels are divided into two main classes:

- optical, the operation of which is based on the refraction of the incoming image in a system of prisms and reflection from the mirror surface;

- laser, the operating principle of which is based on a laser emitter and the construction of one or two planes.

The decision to make a level yourself may be caused by the significant high cost of professional branded instruments, the lack or very limited selection of necessary instruments in provincial retail outlets, or simply curiosity. Spare parts for homemade levels can be purchased without problems and very inexpensively in building materials stores and even office supply stores.

Option No. 1 – Use a flat stand

In the first case, in order to make the device ourselves, we will need the following materials:

- a regular laser pointer, which is sold in kiosks and on the market and is not expensive (shown in the photo below);

- bubble building level, can be bought at a specialty store;

- wooden peg, 1 to 1.3 meters long, 5 to 6 cm in diameter;

- a small piece of rubber;

- a sheet of plywood or board along the length of the level.

Having prepared all the materials, you can proceed to assembling a homemade device. To make it clearer to you how to make a laser level with your own hands, we provide a step-by-step guide:

That's all the manufacturing instructions. As you can see, making a simple laser level with your own hands is not difficult, but the problem is that such a homemade product cannot be installed on a hard surface, for example, a concrete screed or a wooden floor. It is usually used outdoors. To solve this problem, you can also screw a stand made of plywood sheet perpendicularly from the second end of the peg. In addition, you can make a support of a special design, like a real level, but making a tripod will take more time and effort.

Using such a homemade laser pointer device is not difficult. First, the stand is driven into the ground or placed on the floor, after which it is leveled with a bubble level - the bubble should be strictly in the center. Next, you need to turn on the pointer and mark the point projected on the wall with a pencil. After this, the stand carefully rotates along its axis in a horizontal plane, and new marks are placed. All the points are connected to each other and that’s it – the straight line on the wall is ready, you can proceed to other equipment!

It should be noted right away that you should not rush and start important marking work without calibrating the device. First of all, you must make sure that the homemade product works correctly so that the result does not become unexpected for you. To do this, you need to adjust the homemade laser level (in other words, check the accuracy of its operation).

You can make the adjustment yourself like this:

With the help of such a homemade laser device, you can independently draw horizontal lines in your home. However, you should not rely on high measurement accuracy. The device is homemade and has some error, which must be taken into account.

Video review of a more complex self-regulating cross-type model

How to make a level with your own hands

DIY methods

There are several ways to make a device yourself. To do this, you will have to purchase some materials, but most of them can be found in almost any home.

From a laser pointer

The simplest and least expensive option can be made from a regular laser pointer. To do this you will need to buy the pointer itself. In addition to this, you will need:

- a block of wood 50 cm long and with a side size of 25 mm;

- construction cord or its analogues;

- stick to support the finished level;

- drill.

Holes are drilled in the beam at both ends.

One of them is intended for attaching the emitter, and the second is for a cord or rope. The pointer is securely attached to one end, and the cord is threaded through the other end so that it can fit freely in the hole. You can use absolutely any stick for support. Even a shovel stuck in the ground will do. The main thing is to be able to freely hang the resulting structure. The support must be securely fixed, and only this will allow you to obtain the most accurate markings.

This level allows you to mark the necessary surfaces wherever needed, and also use it as a homemade level. When using it, it is preferable to reduce the illumination, which will give clearer marks.

It is better to install the assembled structure within the center of the room. And you can control the accuracy using a stick, on which a mark will be applied when the first point is fixed.

Styrofoam and container with water

This DIY level method is even simpler. All you need to make it is:

- laser pointer;

- a piece of foam;

- plasticine, electrical tape, adhesive tape;

- a small container of water, for example an old saucepan.

It is necessary to attach the laser pointer to the foam as evenly as possible.

Fill the prepared container with water to the very top. Carefully place the foam with the emitter on the surface of the water. Now all that remains is to position the resulting system at the required height. When making the next mark, the foam is turned to the next marked location. When all the points are ready, it is enough to connect them together with a construction tape.

This type of device, although not ideal, allows you to get fairly accurate results.

Emitter in the form of a cross

A more complex, but very accurate laser level is convenient to use in any situation, especially for installing hanging furniture. Although it can only be called complex in relation to others, it is easy to assemble. For this option you will need:

- four laser pointers;

- video camera tripod;

- three CDs;

- old drive from a player or computer;

- material for fastening: tape, plaster, electrical tape.

The use of a tripod is due to the fact that it allows you to place the pointer as level as possible relative to the horizon, move the installed structure horizontally to the required height, and rotate the emitters without disrupting the set parameters.

First, you need to firmly fix the drive from the player to the tripod. Glue the CDs together and install them in the drive. Attach laser pointers to them in the shape of a cross. And the device is completely ready for use.

The advantage of this model is that it can be rotated in any direction, as well as raised and lowered without loss of accuracy. This allows you to hit the level without constant readjustment.

Pendulum system

Having made a simple laser level with your own hands, you can try to create more complex models that are as close as possible to factory analogues. Very accurate data is provided by a level using a pendulum system. In this case, most of the work will be done by the pendulum itself, while the radiating system will not take much force.

In this case, a pointer will not be needed. Instead, a laser module is used with prisms already installed in it, allowing the projection of horizontal and vertical lines.

The module itself runs on three to four AA batteries. This is the optimal number of batteries: two are discharged too quickly, and a larger number makes the system too heavy. You will need a compartment for them; you can take it from an old toy.

The module, batteries and other parts involved in the process must be assembled into one unit. When this part is ready, it needs to be installed on a pendulum prepared in advance. And after that you can think about the body of the structure.

A piece of plastic plumbing pipe, in which holes for the beams are pre-cut, is perfect for it. A switch is also installed here. This completes the level assembly.

But it still has to be calibrated. For these purposes, you can use a water level, which is used to make two marks on the wall at a distance of five to six meters. If the beam coincides with the marks, then no additional adjustment will be needed. Otherwise, you will have to adjust the pendulum.

Option No. 2 – Use a container of water

The second way to make a laser level with your own hands is to use a water surface. All you need is to select a container of suitable size, for example, a basin, and pour water into it under the rim. The liquid forms a plane that will be parallel to the horizon. Next, you need to take a piece of polystyrene foam and secure the pointer strictly in the middle. After this, the container must be set at the level of the future line and the foam with a pointer must be placed in the water. We turn on the homemade product and mark points on the wall, turning the laser in the desired direction. Then we connect them and get a straight horizontal line. The video example shows in detail all the stages of assembling a homemade water level:

Master class on creating a simple device

The disadvantage of this level is that you need to correctly and very evenly attach the pointer to the foam. Otherwise, it will be slightly skewed to one side, which will negatively affect the accuracy of the device. You also need to choose only even pieces of foam in the form of a plate, the sides of which are parallel.

The master quickly assembled the design of the level

To get a level, you need to think about a design that could self-balance. To do this, we will prepare a piece of aluminum, a hard drive bearing.

Let's cut a hole for the bearing. Let's make a rectangle with a cut, and pull the resulting halves together.

The bearing clamped perfectly. Now the structure is able to rotate along its axis. You need to come up with a frame structure in which the unit will fit. And a laser mount. Make a button. The author of the video used a set of buttons. For details, watch the video at the end of the article.

To securely attach the switch to the modules, we first solder it into the circuit board, and then cut out a piece of the required size and glue it onto the board. 3.7 volt lithium batteries are used as a power source. Charge controller with mini USB connector. You can charge it with any cell phone charger. When charging, the red LED lights up, and when the battery is fully charged, the blue LED lights up. To attach the board we use hot melt adhesive. For reliability, you can rewind it with electrical tape. The master decided to abandon the screeds. The charge controller for the level was wrapped with nylon tape. It is transparent and the LEDs will be clearly visible. To monitor the battery status.

Now the question arose about the body of the device, which I didn’t want to do with my own hands, so as not to waste time on it. A junction box purchased at a hardware store came in handy. Costs only 40 rubles. The level will be installed in it as if it were in its original case.

Taking into account the changes, the master decided to remove the button from the internal structure and attach it to the body. The connectors and wires from the kit also came in handy here. I plan to use a clamp to secure the cover of a homemade laser level.

Device setup

The final version of the device must be adjusted along the X and Y axes. This occurs due to the length of the bearing. The level moves along it. This way you can achieve the desired position. To align along the Y axis, additional operations had to be done. The adjustment is carried out according to the water level. The indicator calms down quickly. For stability, we install rubber feet on the bottom of the device.

A homemade device cannot compete with a conventional level, but it is laser, the price is no more than 3 dollars, it is possible to give vertical and horizontal lines.

Details on video

How to mount a laser level with your own hands, and is it even possible? Such a high-tech device for projecting vertical or horizontal surfaces when leveling them is manufactured using high-precision equipment. Professional models use special diode lamps that, using prismatic glass, convert the outgoing light into a thin beam.

This definition sounds somewhat scary. But there is no need to despair, because this applies to professional devices used on construction sites. But such models are not very suitable for home use. There are various options on sale for professional use, as well as for indoor renovation work.

You can purchase household models, but again, after using them once, you will put the device in a drawer, and it is not known when you will need it again. Therefore, we suggest considering the option of making a laser level yourself at home.